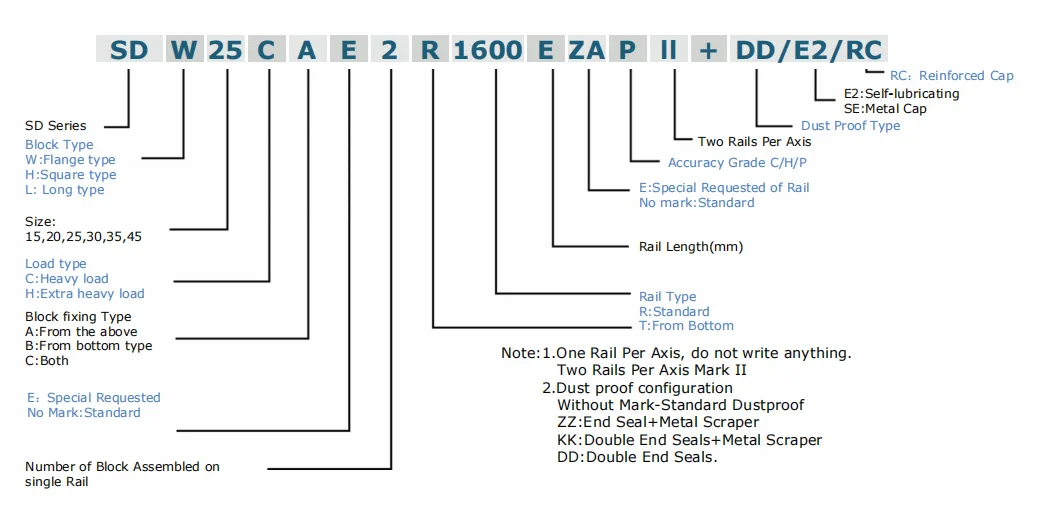

Ball Compact Linear Guide Supplier

>> DTX-LG Ball linear guide interchangeable with Bosch Rexroth BSCL

>>Replace roller linear guide, Boost Your Profit by 30–50%

>> High Torque Capacity

>> Improved stability by 40%

>> Stable Supply & On-Time Delivery

>> Flexible Stocking Support

WHO TRUST US?

DTX-LG Compact Linear Guides For Sale

DTX-LG high-precision, low-friction, durable ball linear guides for CNC, 3D printing, robotics, and automation

Compact Linear Square Block

Block type: Square

Size: 25/30/35/45

Precision Code : C/H/P

Compact linear flange block

Block type: Flange

Size: 25/30/35/45

Precision Code : C/H/P

Compact linear Long block

Block Type: Long

Size: 25/30/35/45

Precision Code : C/H/P

Compact linear Guide rails

Size: 25/30/35/45/

Precision Code : C/H/P

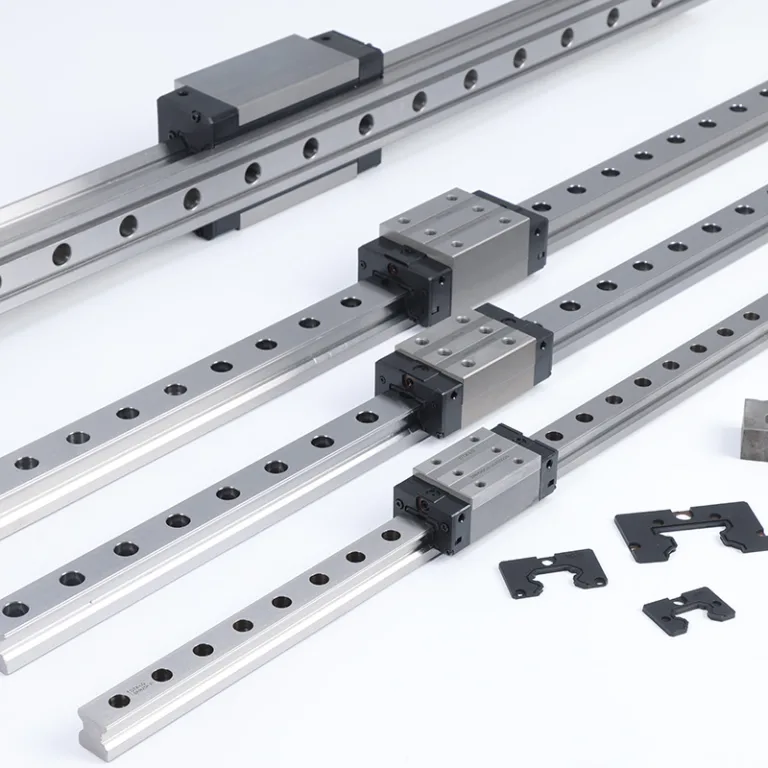

Compact Linear Guide Assembly

Size: 25/30/35/45

Precision Code : C/H/P

Ball Linear Guide Assembly

Size: 15/20/25/30/35/45/55/65

Precision Code : C/H/P

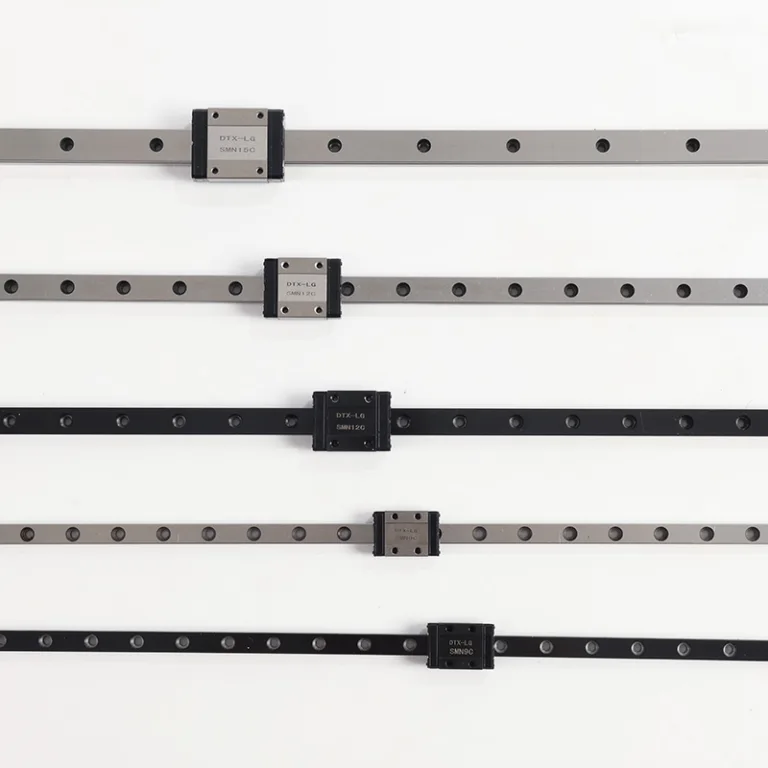

Miniature Linear Guide Assembly

Size: 5/7/9/12/15

Precision Code : C/H/P

Roller Linear Guide Assembly

Size: 25/30/35/45/55/65/85/100

Precision Code : H/P/SP/UP

user or distributor — we deliver exactly what you need

*Good wear resistance

*Premium matte appearance

*Smooth, low-friction surface

*Stable corrosion protection

*Custom logos can be laser-engraved on the product

Highlight of DTX-LG Compact linear guide

DTX-LG compact linear guide sliders compared to an X-array configuration, this design offers higher torque capacity and improved torsional stiffness, resulting in enhanced stability, higher load capability, and more consistent performance in demanding applications.

The DB (back-to-back) contact angle design significantly improves anti-overturning capability, making it especially suitable for Z-axis applications and cantilever structures.In many medium to heavy load machining scenarios, the DB series delivers performance close to roller linear guides, enabling reliable operation without overengineering.

Recirculating compact linear guides smooth and precise operation with consistent starting torque. P-grade accuracy in dimensions, combined height, paired block height, and running parallelism ensures reliable performance. Rails can be seamlessly joined up to 100 m, maintaining joint gaps below 0.1 mm and perpendicularity under 0.03 mm for ultra-stable long-distance motion.

Thanks to the four-row ball configuration, the carriage maintains two-point contact under loads from all directions. This balanced load distribution minimizes internal friction and ensures smooth, stable movement, resulting in higher positioning accuracy, lower driving force requirements, and extended service life.

DTX-LG linear guides feature excellent dimensional accuracy and standardized design, ensuring high interchangeability. They can directly replace major brands like THK and HIWIN, offering a cost-effective alternative.

DTX-LG operates eight production facilities across northern and southern China, with 108 precision machining lines for rails and carriages, running 24/7 to ensure the fastest delivery worldwide.

Free Samples Available!

We’re glad to provide you with free samples. You can choose to pay for shipping either upon receipt or in advance. Just let us know what you need, and we’ll ensure your satisfaction before you make a purchase.

DTX-LG Linear Guides System Interchangeability

| DTX | HIWIN | CSK | ABBA | TBI | THK | IKO |

| SGW15CA | HGW15CA | DGW15CA | BRH15A | TRH15FL | HSR15A | LWH(HT)15B |

| SGW20CA | HGW20CA | DGW20CA | BRH20A | TRH20FL | HSR20A | LWH(HT)20B |

| SGW20HA | HGW20HA | DGW20HA | BRH20AL | TRH20FE | HSR20LA | LWH(HT)G20B |

| SGW25CA | HGW25CA | DGW25CA | BRH25A | TRH25FL | HSR25A | LWH(HT)25B |

| SGW25HA | HGW25HA | DGW25HA | BRH25AL | TRH25FE | HSR25LA | LWH(HT)G25B |

| SGW30CA | HGW30CA | DGW30CA | BRH30A | TRH30FL | HSR30A | LWH(HT)30B |

| SGW30HA | HGW30HA | DGW30HA | BRH30AL | TRH30FE | HSR30LA | LWH(HT)G30B |

| SGW35CA | HGW35CA | DGW35CA | BRH35A | TRH35FL | HSR35A | LWH(HT)35B |

| SGW35HA | HGW35HA | DGW35HA | BRH35AL | TRH35FE | HSR35LA | LWH(HT)G35B |

| SGW45CA | HGW45CA | DGW45CA | BRH40A | TRH45FL | HSR45A | LWH(HT)45B |

| SGW45HA | HGW45HA | DGW45HA | BRH40AL | TRH45FE | HSR45LA | LWH(HT)G45B |

| SGW55HA | HGW55HA | DGW55HA | BRH55A | TRH55FL | HSR55A | LWH(HT)55B |

| SGH15CA | HGH15CA | LMG15H | BRH158 | TRH15VL | HSR15R | LWHD15B |

| SGH20CA | HGH20CA | LMG20H | BRH20B | TRH20VL | HSR20R | / |

| SGH20HA | HGH20HA | LMG20LH | BRH20BL | TRH20VE | HSR20LR | / |

| SGH25CA | HGH25CA | LMG25H | BRH25B | TRH25VL | HSR25R | LWHD25B |

| SGH25HA | HGH25HA | LMG25LH | BRH25BL | TRH25VE | HSR25LR | LWHDG25B |

| SGH30CA | HGH30CA | LMG30H | BRH30B | TRH30VL | HSR30R | LWHD30B |

| SGH30HA | HGH30HA | LMG30LH | BRH30BL | TRH30VE | HSR30LR | LWHDG30B |

| SGH35CA | HGH35CA | LMG35H | BRH35B | TRH35VL | HSR35R | LWHD35B |

| SGH35HA | HGH35HA | LMG35LH | BRH35BL | TRH35VE | HSR35LR | LWHDG35B |

| SGH45CA | HGH45CA | LMG45H | BRH45B | TRH45VL | HSR40R | LWHD45B |

| SGH45HA | HGH45HA | LMG45LH | BRH45BL | TRH45VE | HSR40LR | LWHDG45B |

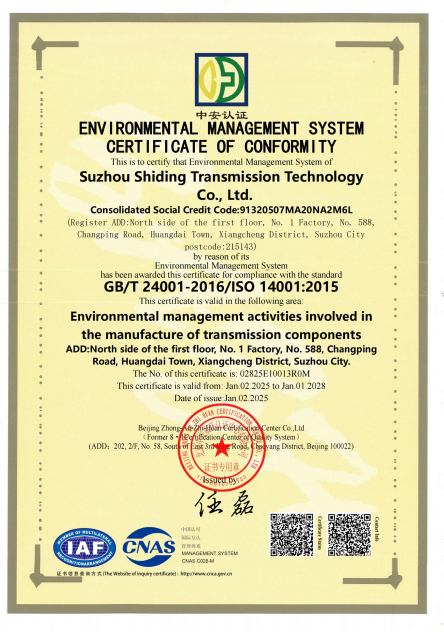

Certificates and Patents

DTX-LG linear guide come with a host of certifications—functional and design patents, ISO 9001, ISO 13485, ISO 45001, ISO 14001, virus & bacterial filtration tests, and more. We continually add credentials to ensure quality.

Questions? You’re covered

As a linear guide rails manufacturer, DTX-LG offers professional linear rail system service from R&D and production to final adjustment. We look forward to exploring new challenges with you.

01. What does the DB structure mean in linear guides?

DB stands for Back-to-Back contact angle design, where the load contact angles face outward. This structure provides higher rigidity and stronger resistance to overturning moments compared to standard DF designs.

02. Can the DTX-LG DB series replace roller linear guides?

In many medium to heavy load applications, yes. The DB series can cover part of the roller guide usage scenarios, offering comparable stability and rigidity at a significantly lower cost.

03. What are the main advantages of the DB series compared to roller guides?

The key advantages include lower cost, easier installation, higher speed capability, and simpler maintenance, while still providing excellent rigidity and load stability.

04. Is the DB series suitable for Z-axis applications?

Yes. Thanks to its enhanced moment load capacity and anti-overturning design, the DB series performs particularly well in vertical (Z-axis) and suspended load applications.

05. What cost savings can be expected when switching from roller guides?

Customers typically achieve significant cost reductions in both component cost and total machine BOM, without sacrificing the performance required for their application.

Want a quick quote?

Receive requests and quotations

*No model? Just share dimensions or usage—we’ll recommend one.

*Get a quote based on your specs: model, size, quantity, etc.

Confirm samples

* All samples are securely packed to ensure they arrive in good condition.

Production on demand

*Our production follows ISO standards to ensure precision and consistency.

Delivery and suppoet

*Multiple shipping options are available: sea, air, or express (DHL/UPS/FedEx).

Want a quick quote?

Please fill out the form below — our engineer will contact you shortly based on the information you provide.