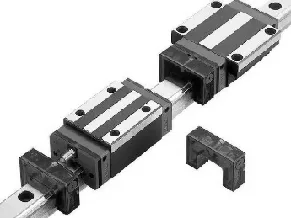

Low Profile Linear Guide Rail Carriage Assemblies

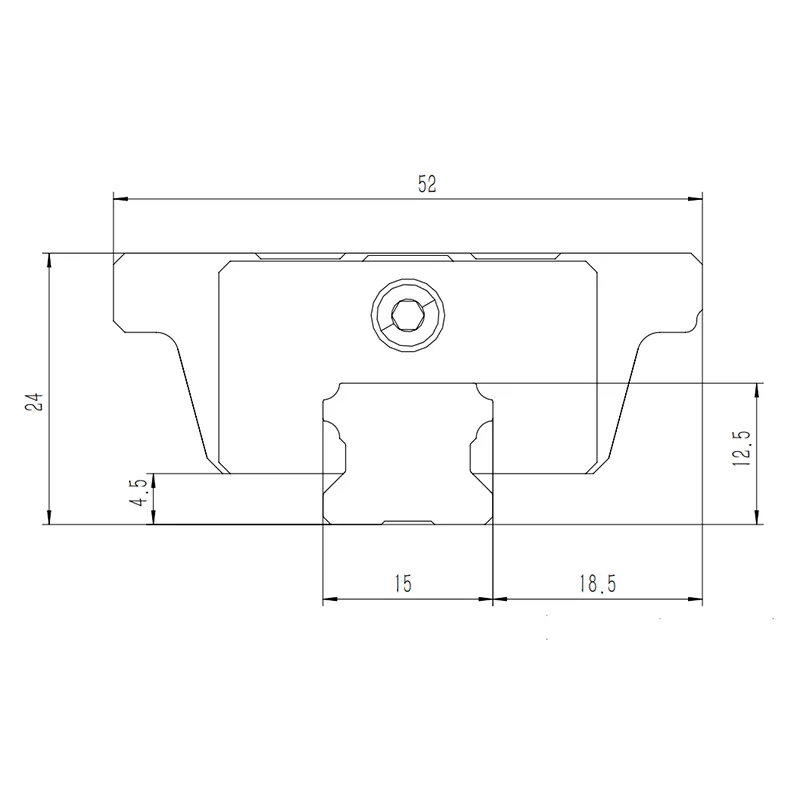

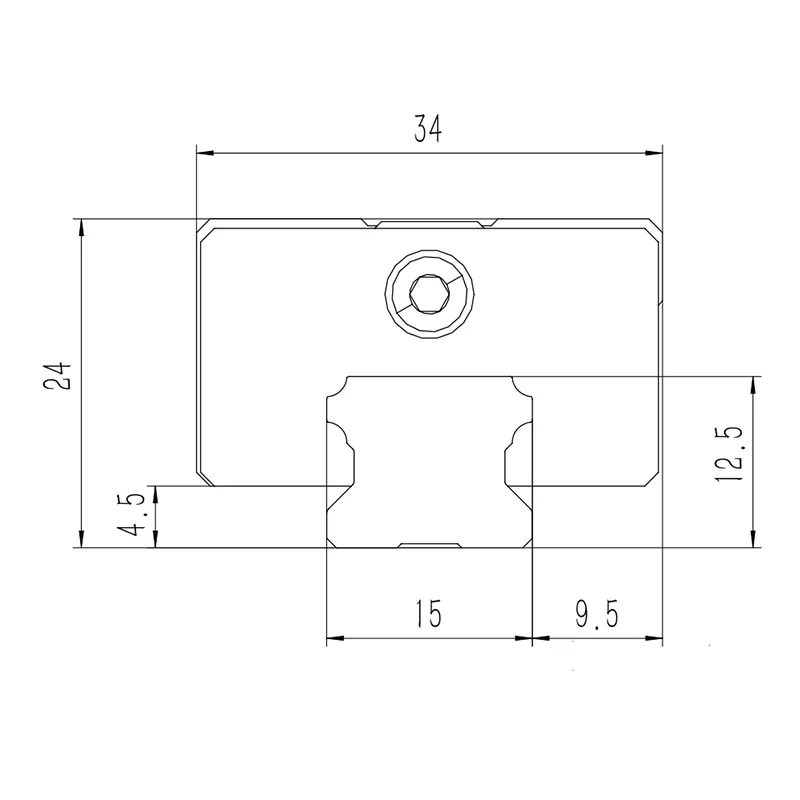

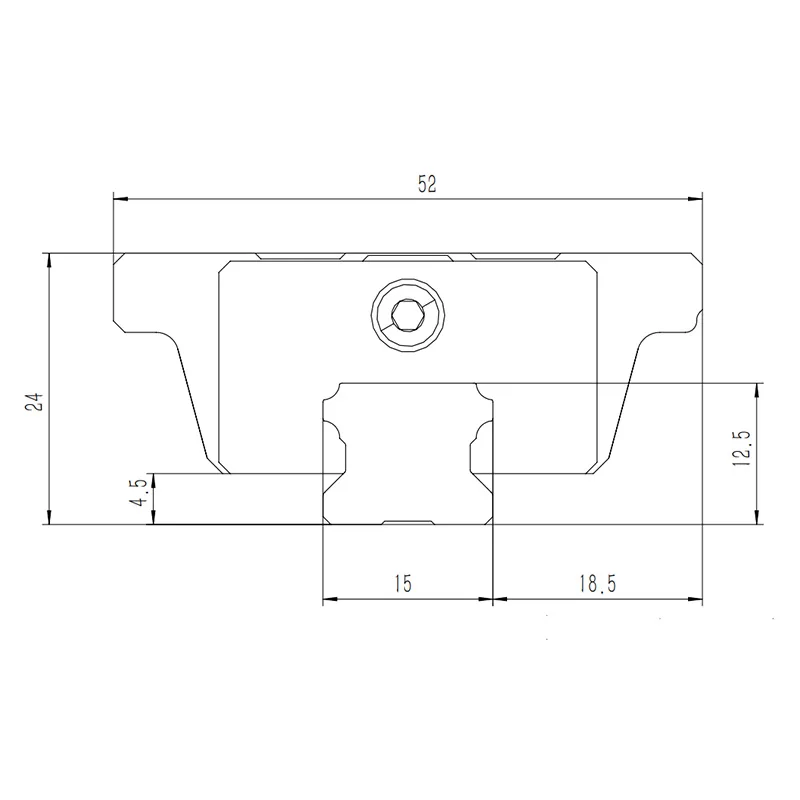

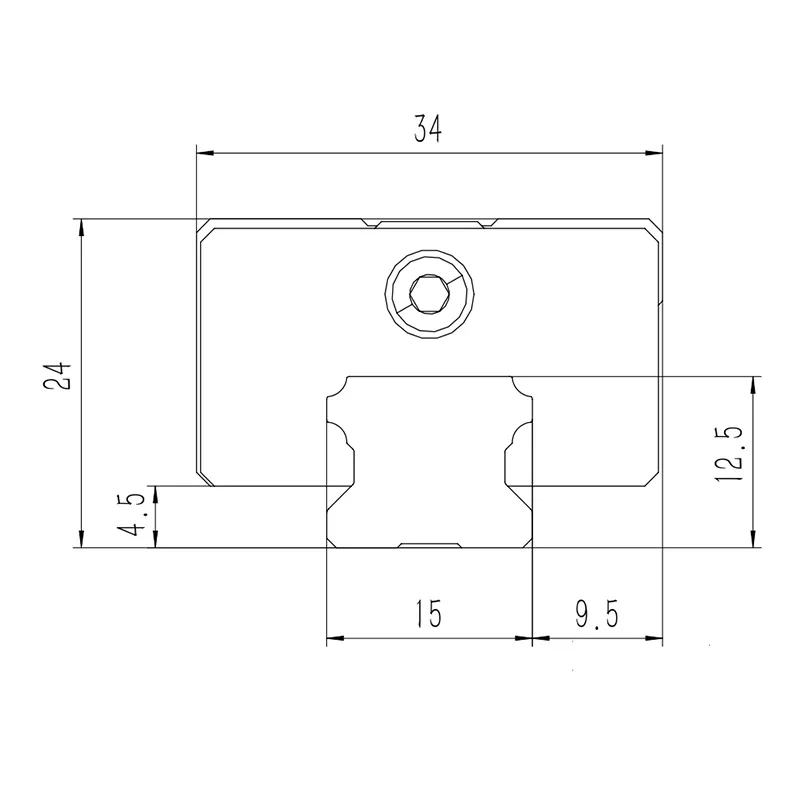

SE 15/20/25/30/35

Hiwin eG series interchangeable linear rail system

Low Profile Ball Type Linear Guide Rail For Sale

- Rail length: up to 6 m

- Block types: square / flange / extended square

- Accuracy grades: C, H, P, SP, UP

- Sizes: 15, 20, 25, 30, 35

- Block mounting types: top mounting / bottom mounting / top or bottom mounting

- Corrosion protection: hard chrome plating, black chrome plating

- Dust protection options: 1.Oil scraper + end seal + metal scraper 2.Double oil scraper + end seal + metal scraper 3.Double oil scraper + end seal

Why DTX-LG low profile linear guides?

- Flexible MOQ

- Competited Price

- High Customization

- Professional Support & Service

- Quality Assurance

- Full Interchangeability

- Good running smoothness

- Significant Cost Advantage

01. High-Strength Materials

DTX-LG linear guide rail and carriage is manufactured from premium steel and undergoes advanced heat treatment, achieving a surface hardness of 59–62 HRC. This ensures excellent wear resistance, higher load capacity, and extended service life even under heavy-duty conditions.

Each precision flanged linear block is equipped with high-quality steel balls hardened to 61–66 HRC. The superior hardness provides outstanding rolling performance, enhances load distribution, and guarantees smooth, precise linear motion with minimal friction.

02. Design in Taiwan, made in china

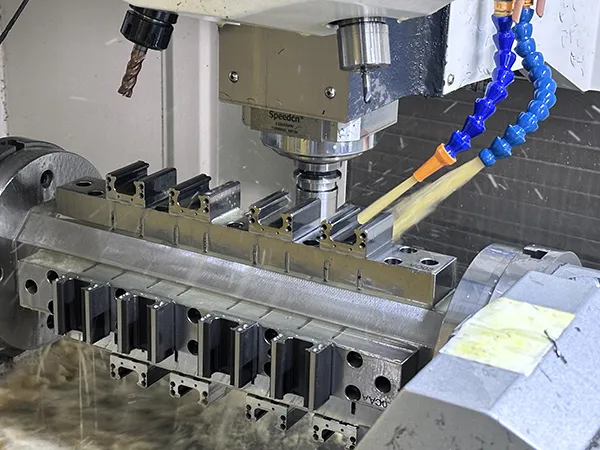

Each linear rail and blocks corrosion resistant carriage is manufactured in-house with CNC drilling and grinding to ensure accuracy and consistency. With 16 production lines and an annual output of 3,600,000 pieces, DTX-LG guarantees strict quality control, large-scale supply, and reliable delivery worldwide.

03. Advanced Self-Lubrication System

A built-in lubrication mechanism is integrated into the end cap, consisting of an oil storage unit and an oil release unit. The oil guide element inside not only absorbs and stores oil but also gradually releases it to the raceway through its special structure. This design ensures continuous lubrication, significantly reduces maintenance requirements, and keeps the block running reliably over long periods. Idea flanged linear block for CNC machine.

04. Ensuring Cleanliness and Reliability Before Assembly

Each linear rails and bearing blocks undergoes a thorough ultrasonic cleaning process to remove machining residues, fine metal particles, and surface impurities. This is followed by hot air drying to eliminate moisture and prevent corrosion. Only after these cleaning and drying steps are completed does the block proceed to the assembly stage, ensuring that every linear motion components maintains a clean, contaminant-free surface for smooth motion and long-term reliability.

05. A Full-Cycle ISO Quality Management System

DTX-LG has obtained multiple ISO certifications and fully implements standardized ISO quality assurance management processes across every stage of production. From raw material inspection and machining to assembly and final testing, each step strictly follows ISO guidelines. This ensures product consistency, traceability, and compliance with international quality standards, reinforcing our commitment to delivering reliable and globally recognized linear guide rail & carriage assemblies.

The DTX-LG low profile linear guide assemblies are fully dimensionally compatible with the Hiwin EG series. Unlike the SG series, the SE series reduces both the block height and overall block length while maintaining excellent load capacity and rigidity. This low profile linear guide design minimizes installation height and shortens carriage length, making it ideal for applications where space and precision are critical.

These linear guide rail carriage assemblies are widely used in semiconductor equipment, laser processing machines, precision measuring instruments, industrial robots, medical devices, and office automation systems. By lowering the center of gravity, the SE series improves machine stability and motion performance.

With a standardized design, DTX-LG products are fully interchangeable with THK, IKO, Hiwin EG, TBI, and PMI equivalents, allowing simple replacement without machine redesign.

As a professional low profile ball type linear guide supplier, DTX-LG not only offers standard steel linear guide assemblies, but also optional surface treatments including black chrome plating, hard chrome plating, and anti-corrosion coatings. These treatments enhance wear resistance, reduce noise, and minimize light reflection, making DTX-LG an ideal choice for high-end precision equipment manufacturers.

Questions? You’re covered

As a linear guide assembly manufacturer, DTX-LG offers professional service from R&D and production to final adjustment. We look forward to exploring new challenges with you.

01. Can DTX-LG support large-volume OEM projects?

As a low profile ball type linear guide supplier, we specialize in high-volume manufacturing with consistent quality and competitive pricing.

02.Do you provide engineering drawings and technical support?

Yes. DTX-LG supply low profile linear guide rail systems CAD models, installation manuals, and technical guidance to ensure proper assembly and performance.

03. What is your production and delivery time for bulk orders?

With 24/7 automated production, we maintain stock for standard good quality low profile ball type linear guide sizes and provide fast lead times for distributors.

04. Can I order custom lengths for the rails?

Absolutely. DTX-LG provide rails cutting to specific lengths and provide precision-drilled mounting holes based on your requirements.

05. What applications are these low profile linear guides suitable for?

Linear rail guide with bearing block are widely used in semiconductor equipment, laser machines, precision measuring instruments, industrial robots, medical devices, and office automation.

06. Are DTX-LG low profile linear guide assemblies compatible with Hiwin EG series?

Yes. DTX-LG linear guide rail carriage assemblies match Hiwin EG dimensions, allowing direct replacement without redesign.

Want a quick quote?

Please fill out the form below — our engineer will contact you shortly based on the information you provide.