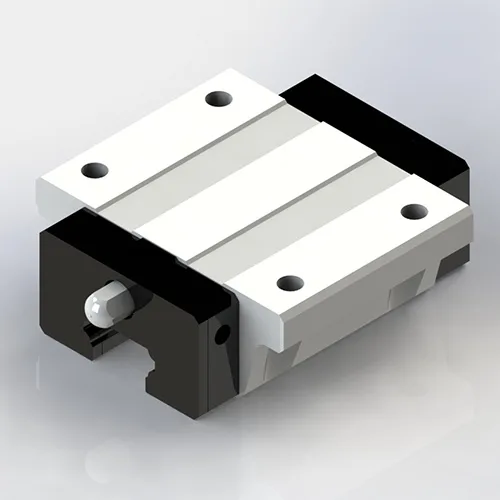

Low Profile Linear Guide Block SEW

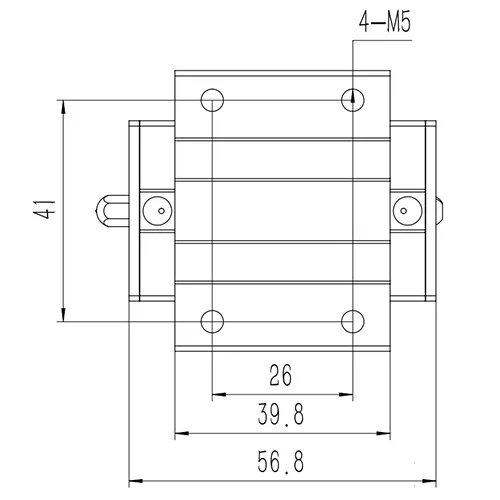

SEW 15/20/25/30/35

Interchangeable with EGW15SA/B EGW15CA/B EGW20SA/B EGW20CA/B EGW25SA/B EGW25CA/B EGW30SA/B EGW30CA/B

- Block types: flange

- Accuracy grades: C, H, P

- Material:Standard/Full Metal

- Sizes: 15, 20, 25, 30, 35

- Block mounting types: top mounting / bottom mounting / top or bottom mounting

- Dust protection options: 1.Oil scraper + end seal + metal scraper 2.Double oil scraper + end seal + metal scraper 3.Double oil scraper + end seal

Why DTX-LG linear guideway carriage?

- Flexible MOQ

- Competited Price

- High Customization

- Professional Support & Service

- Quality Assurance

- Full Interchangeability

- Good running smoothness

- Significant Cost Advantage

01. High-Strength Materials

DTX-LG linear rail carriage is manufactured from premium steel and undergoes advanced heat treatment, achieving a surface hardness of 59–62 HRC. This ensures excellent wear resistance, higher load capacity, and extended service life even under heavy-duty conditions.

Each precision flanged linear block is equipped with high-quality steel balls hardened to 61–66 HRC. The superior hardness provides outstanding rolling performance, enhances load distribution, and guarantees smooth, precise linear motion with minimal friction.

02. Design in Taiwan, made in china

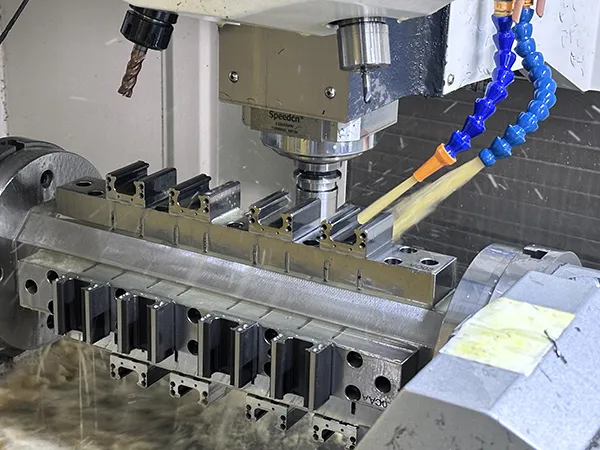

Each china linear guide carriage SEW corrosion resistant carriage is manufactured in-house with CNC drilling and grinding to ensure accuracy and consistency. With 16 production lines and an annual output of 3,600,000 pieces, DTX-LG guarantees strict quality control, large-scale supply, and reliable delivery worldwide.

03. Advanced Self-Lubrication System

A built-in lubrication mechanism is integrated into the end cap, consisting of an oil storage unit and an oil release unit. The oil guide element inside not only absorbs and stores oil but also gradually releases it to the raceway through its special structure. This design of linear slide carriage ensures continuous lubrication, significantly reduces maintenance requirements, and keeps the block running reliably over long periods. Idea flanged linear block for CNC machine.

04. Ensuring Cleanliness and Reliability Before Assembly

Each heavy-duty linear guide block undergoes a thorough ultrasonic cleaning process to remove machining residues, fine metal particles, and surface impurities. This is followed by hot air drying to eliminate moisture and prevent corrosion. Only after these cleaning and drying steps are completed does the block proceed to the assembly stage, ensuring that every SGH block maintains a clean, contaminant-free surface for smooth motion and long-term reliability.

05. A Full-Cycle ISO Quality Management System

DTX-LG has obtained multiple ISO certifications and fully implements standardized ISO quality assurance management processes across every stage of production. From raw material inspection and machining to assembly and final testing, each step strictly follows ISO guidelines. This ensures product consistency, traceability, and compliance with international quality standards, reinforcing our commitment to delivering reliable and globally recognized linear guide rail & carriage assemblies.

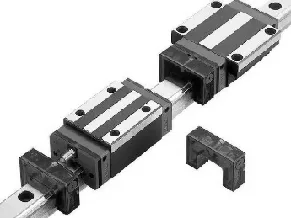

DTX-LG low profile linear guide block flanged SEW are fully interchangeable with hiwin egw, including hiwin HGW 15, hiwin HGW 25, hiwin HGW 30, hiwin HGW 45, and hiwin HGW 65. Designed for applications with limited height in the vertical direction, the flanged type allows both top and bottom mounting with a larger support span to resist overturning moments more effectively. Optional metal scrapers protect against machining sparks, high-temperature chips, and large particles. The DTX-LG self-lubrication system uses the capillary effect between flexible materials of different densities, enabling lubricant to transfer gradually for long-lasting performance. Ideal for gantry systems and Z-axis applications where vertical space is restricted, these flanged carriage blocks are also widely used in automation pick-and-place modules, 3D printer extruder motion systems, and other high-precision equipment.

Questions? You’re covered

The SGW series linear block from DTX-LG is a precision-engineered linear motion component that is Hiwin HGW replacement.

01. What kind of linear rail is compatible with SEW blocks?

SEW blocks are compatible with standard linear rails used with Hiwin EGW carriages, ensuring quick integration or replacement.

02. Is SEW block a good alternative in terms of price and performance?

Definitely. SEW compact linear block from DTX-LG offer the same performance as Hiwin EGW blocks but at a much more competitive price.

03. Can I order SEW blocks with matching rails as a complete guide system?

Yes. DTX-LG supplies SEW blocks individually or together with precision-matched linear rails for your complete precision linear motion system needs.

04. Are low-profile flanged linear block suitable for light-load or high-speed applications?

Yes, the SEW series is a kind of vertical linear carriages, pecifically designed for high-speed and low-to-medium load applications, just like the Hiwin EGW blocks.

05. What are the key features of the SEW flanged linear block?

SEW linear motion carriage block feature a compact design, flange-type mounting for added stability, smooth linear motion, and are ideal for space-constrained applications.

Want a quick quote?

Please fill out the form below — our engineer will contact you shortly based on the information you provide.