-

12/19/2025

- 0 Comment

How Linear rails guide Work on Ender 3/5 3d printer?

Table of Contents

Upgrade Your 3D printer with miniature linear guide

Within the 3D printing enthusiast community, the Creality Ender 3 and Ender 5 series have won the favor of millions of users worldwide thanks to their exceptional cost-performance ratio and massive modding potential. From hotend upgrades and auto-bed leveling to mainboard swaps and firmware experiments, among the many upgrade options, replacing the stock linear bearings or rod systems with micro linear guides—is quietly becoming the “secret weapon” for users pursuing ultimate print quality.

What is Ender 3/Ender 5 3D printer?

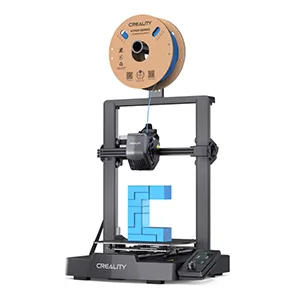

The Ender 3 and Ender 5 are two of the best-selling and most representative consumer-grade 3D printer models from Creality, a globally renowned 3D printer manufacturer. Most of their hardware and software are open-source, with a wealth of free tutorials, modification options, and community support.

- The Ender 3 3D printer features the most classic and common 3D printer structure.

It has a simple structure, highly interchangeable parts, and an affordable price. However, the moving Y-axis heated bed may shake due to inertia during high-speed printing, affecting accuracy. When printing tall objects, the Z-axis frame may experience slight shaking.

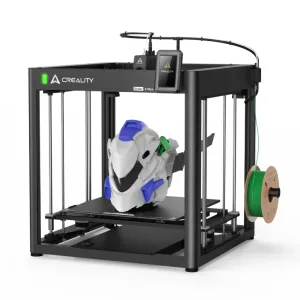

- The Ender 5 3D printer has a stable, cubic form factor.

It is more stable during high-speed printing, with less resonance and higher accuracy.

The X-axis beam is single-sided supported (cantilevered), which may result in less rigidity compared to the Ender 3’s dual-pillar support.

How to upgrade with 3d printer rail?

Upgrading ender 3 y axis linear rail

- For the Ender 3: Upgrading ender 3 y axis linear rail is crucial for stabilizing the moving, heavier heated bed; upgrading the X-axis allows for smoother print head movement.

Upgrading ender 5 or 5plus X axis and Y axis linear rail

- For the Ender 5 or plus: Upgrading the X axis and Yaxis linear rail maximizes the speed and accuracy potential of its CoreXY motion system, making the print head, which moves rapidly on a plane, more precise and stable.

why are linear rails better for 3d printer?

Miniature profile rail guides improve print precision and consistency by replacing plastic wheels with a rigid metal construction, which eliminates wobble and wear deformation. Their industrial durability reduces maintenance and helps the printer maintain its performance over time. This upgrade is ideal for users seeking higher speed, heavy toolheads, or maximum reliability, as it enhances the core motion system rather than fixing other unrelated issues.

| Dimension | Before Upgrade (Stock Wheels/Bearings) | After Upgrade (With Micro Linear Guides) |

|---|---|---|

| Print Quality | Visible layer lines, ghosting, uneven first layers | Smoother surfaces, sharp corners, consistent first layers |

| Performance | Wobble, uneven friction, frequent adjustments | Stable, near-zero play, smooth motion, quiet operation |

| Durability | Parts wear out, performance declines over time | Long-lasting precision, minimal wear, dust-resistant |

| User Experience | Regular maintenance needed, limited speed | Low maintenance, higher reliable print speeds |

| Cost Over Time | Low upfront cost but ongoing replacement/waste | Higher initial investment but lower long-term cost |

Choosing chrome-plated micro linear guide

In many workshops or home environments, there may be fine moisture or corrosive gases in the air. Even with basic rust prevention treatment, ordinary carbon steel rails may still rust after prolonged exposure. Even the slightest rust spots on the rail surface will act like sandpaper, accelerating wear on the ball bearings and slider, causing vibration, noise, and ultimately leading to a permanent decrease in accuracy or even jamming. Purchasing chrome-plated miniature linear guides effectively resists corrosion from humid environments and common chemicals, protecting the core of the guide and extending its lifespan by several times.

Comparison: Chrome-Plated vs. Non-Plated 3d print linear rail

| Aspect | Non-Plated / Standard Micro Guide | Chrome-Plated Micro Guide (DTX-LG) |

|---|---|---|

| Surface | Basic coating (e.g., black oxide) | Hard chrome plating (mirror finish) |

| Rust Prevention | Fair, can rust in humid conditions | Excellent, strong barrier against moisture & corrosion |

| Hardness & Wear | Softer, wears faster over time | Harder surface, significantly more wear-resistant |

| Precision Over Time | Can lose accuracy due to wear | Maintains high precision for much longer |

| Smoothness | Good, but friction may increase | Lower, more consistent friction, smoother motion |

| Maintenance | Needs regular care to prevent rust | Low maintenance, easy to clean |

| Cost Over Time | Lower upfront, may need earlier replacement | Higher upfront, better long-term value |

| Best For (Ender 3/5) | Dry environments, casual use | Humid environments, high-speed/ precision printing, long-term projects |

Choosing reliable 3d printer linear rail supplier

DTX-LG as linear guides supplier/manufacturer, has provided high-quality 3d printer linear rails to over 20 well-known 3D printer manufacturers across China, with annual sales exceeding 100,000 meters of miniature guides.

Full range of chrome-plated miniature linear guides: DTX-LG understands the importance of rust prevention for long-term accuracy.

Therefore, chrome plating is our standard process for all relevant miniature linear guide products, not an extra-cost option. We promise that every guide we provide will have this reliable protective coating.

Consistent quality through scaled production: With our modern production facilities and large-scale manufacturing capabilities, we can ensure the consistent high quality of every batch of products. From material selection and precision grinding to chrome plating and rigorous testing, our comprehensive quality control ensures that the guides you receive have excellent linear accuracy, low operating noise, and long-term reliability.

Optimized for modification: We fully understand the modification needs of Ender 3, Ender 5, and other mainstream 3D printer models, and offer a variety of guide and slider combinations in different sizes, such as SMN7 (MGN7), SMN9 (MGN9), SMN12 (MGN12)and lengths.