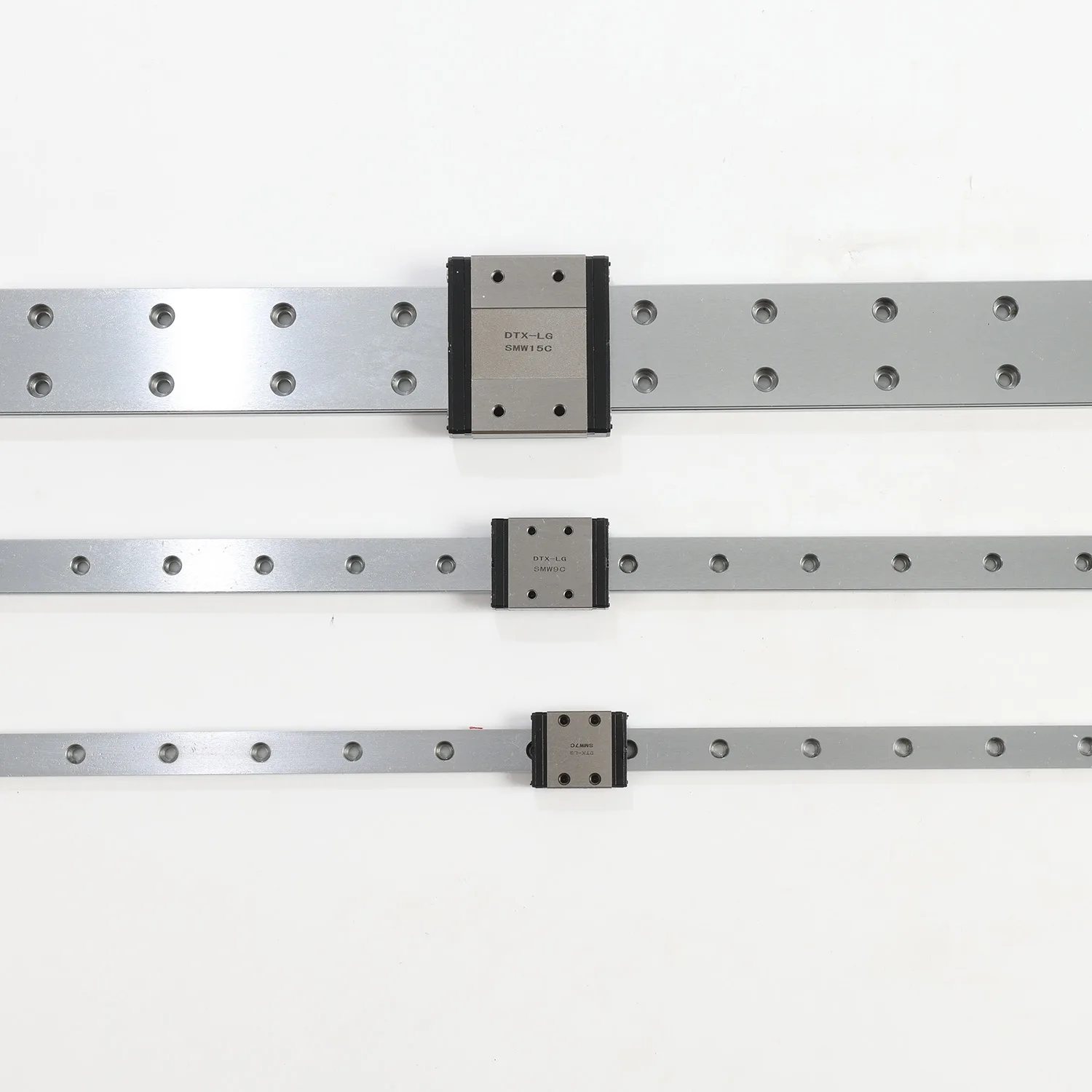

SMW - Bộ Ghép Thanh Dẫn Hướng Khổ Rộng

SMW 5/7/9/12/15

Hiwin MGW系列互换型直线导轨与滑轨

- Chiều dài ray:tối đa 6 m

- Các loại khối tuyến tính:标准型/加长型

- Cấp độ chính xác:C、H、P型

- Kích thước: 5, 7, 9, 12, 15

- 滑块安装类型Gắn phía trên / Gắn phía dưới / Gắn phía trên hoặc phía dưới

- Tùy chọn vật liệu: Thép không gỉ, mạ crôm đen, mạ crôm cứng

为何选择DTX-LG直线滑块?

- Linh Hoạt MOQ (Mức Đặt Hàng Tối Thiểu)

- Giá Cạnh Tranh

- Tùy Chỉnh Cao

- 专业支持与服务

- Đảm Bảo Chất Lượng

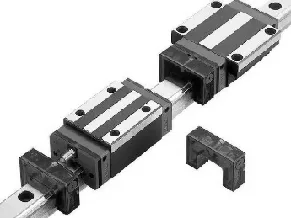

- Tính Năng Thay Thế Hoàn Toàn

- Chạy êm mượt

- Lợi thế chi phí đáng kể

01. 高强度材料

DTX-LG直线导轨与滑块采用优质钢材制造,并经过先进的热处理工艺,表面硬度达到59–62 HRC。这确保了卓越的耐磨性、更高的负载能力,即使在重载工况下也能延长使用寿命。

每个精密法兰直线滑块均配备硬化至61–66 HRC的优质钢球。卓越的硬度提供了出色的滚动性能,改善了负载分布,并保证了平稳、精确的直线运动,同时摩擦极小。

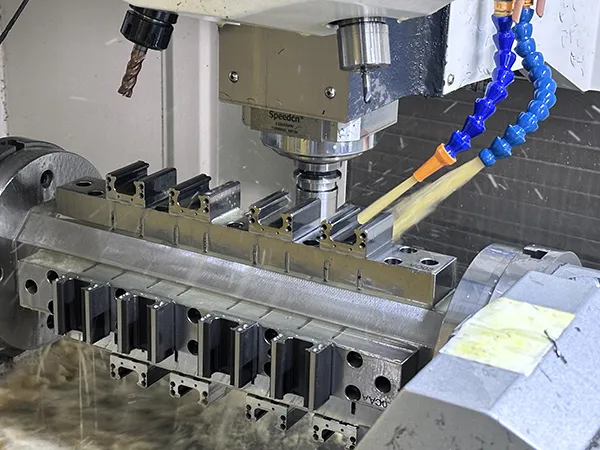

02. 台湾设计,中国制造

每条高品质宽幅直线导轨均在自有工厂通过CNC钻孔与磨削工艺加工而成,确保精度与一致性。凭借16条生产线及3,600,000件的年产量,DTX-LG可保证严格的质量管控、大规模供应能力及可靠的全球交付。

03. 先进的自润滑系统

端盖中集成了内置润滑机构,该机构由一个储油单元和一个释油单元组成。内部的导油元件不仅能吸收和储存润滑油,还能通过其特殊结构将润滑油逐渐释放到滚道中。此设计确保持续润滑,显著减少维护需求,并保证滑块长期可靠运行。是数控机床的理想法兰直线滑块。

04. 装配前确保清洁度与可靠性

每个带滑块直线导轨均经过全面超声波清洗流程,以去除加工残留物、细微金属颗粒及表面杂质。随后进行热风干燥以消除湿气并预防腐蚀。仅当完成这些清洁干燥步骤后,滑块才会进入组装阶段,确保所有直线运动部件保持洁净无污染的表面,实现平稳运行与长期可靠性。

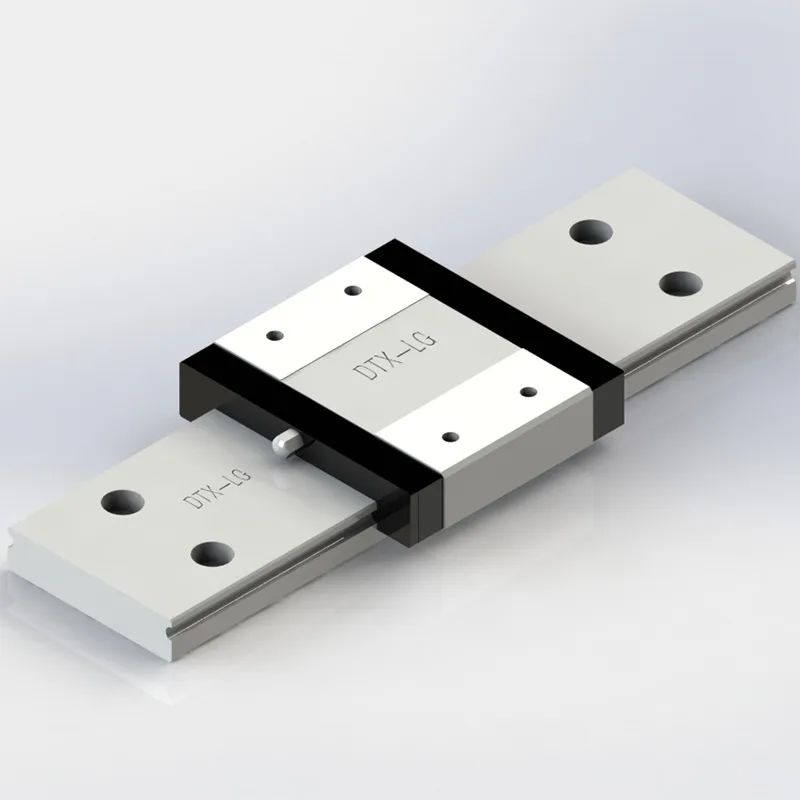

DTX-LG宽幅微型直线导轨与Hiwin MGW系列尺寸兼容。当负载偏离中心或存在悬臂受力时,会产生倾覆力矩导致滑块倾斜。在此类工况下,标准窄幅微型导轨往往会出现显著精度损失甚至损坏。

得益于宽幅导轨设计,DTX-LG宽系列产品提供更大的支撑面,可轻松承受高倾覆力矩。这些宽幅低矮型直线导轨是大型工业机器人关节与手臂、立式加工中心刀塔、激光切割机横梁以及承载重型传感器的精密检测模块等应用的理想选择。

标准化设计确保与THK、IKO、HIWIN、TBI及PMI同类产品完全互换,使更换简便且经济高效。

作为短宽型直线导轨的专业供应商,DTX-LG不仅提供标准钢制组件,还配备多种表面处理工艺,包括黑铬镀层、硬铬镀层及防腐蚀涂层。这些处理能提升耐磨性、降低噪音并防止反光,使DTX-LG成为高端精密设备制造商值得信赖的直线运动导轨滑块及直线轴承滑块批发解决方案。

Có câu hỏi? Đã có chúng tôi

作为直线导轨总成制造商,DTX-LG提供从研发、生产到最终调试的专业服务。我们期待与您共同探索新挑战。

01. 为何选择宽幅低矮型直线导轨而非标准微型直线导轨?

宽幅导轨提供更大支撑面并抵抗倾覆力矩,防止偏载工况下的精度损失。

02. 此类短宽型直线导轨最适合哪些应用场景?

它们特别适用于大型工业机器人关节、激光切割机横梁、立式加工中心刀塔及精密检测模块。

03. 是否可为OEM项目批量供应直线运动导轨滑块?

可以。DTX-LG专精于面向经销商及OEM客户的批量供应,品质稳定且价格具竞争力。

04. 贵司宽幅直线导轨在重载条件下表现如何?

增加的导轨宽度与滑块支撑显著提升刚性,使其具备更高的载荷及力矩承受能力。

05. 是否提供CAD模型与技术图纸?

是的。DTX-LG提供完整2D/3D图纸,便于直接集成至设备设计中。

06. 宽幅低矮型直线导轨的交期如何?

DTX-LG备有标准尺寸库存,并可针对定制订单提供快速生产与运输服务。

Bạn có muốn nhận báo giá nhanh không?

Vui lòng điền vào biểu mẫu bên dưới — kỹ sư của chúng tôi sẽ liên hệ với bạn sớm dựa trên thông tin bạn cung cấp.