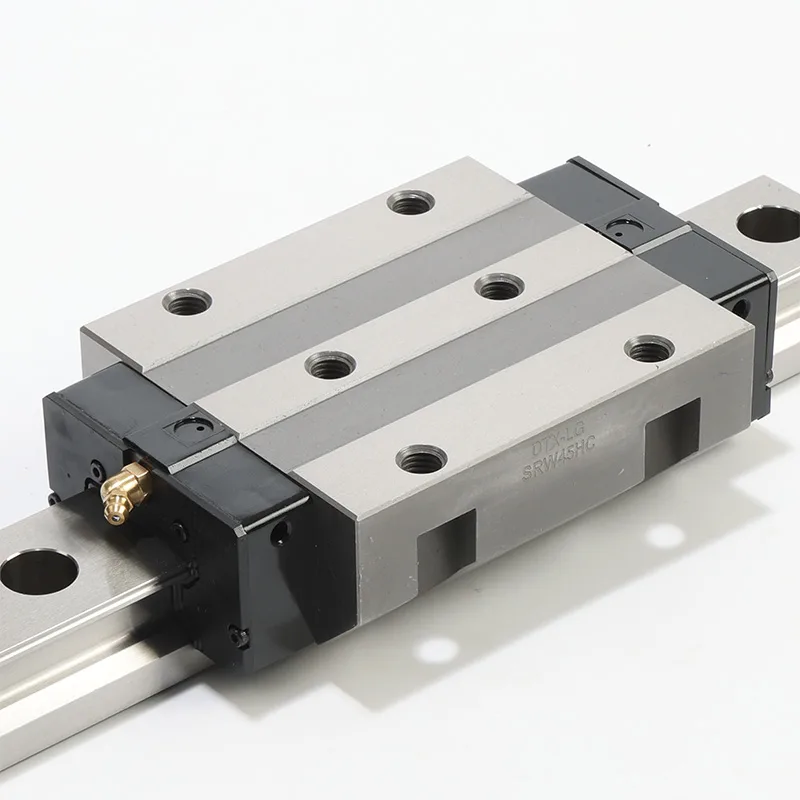

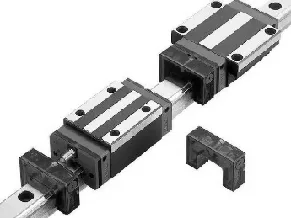

Blocco Guide Lineari a Rulli SRW

SRW 15/20/25/30/35/45/55/65/85/100

Blocco lineare intercambiabile Hiwin RGW

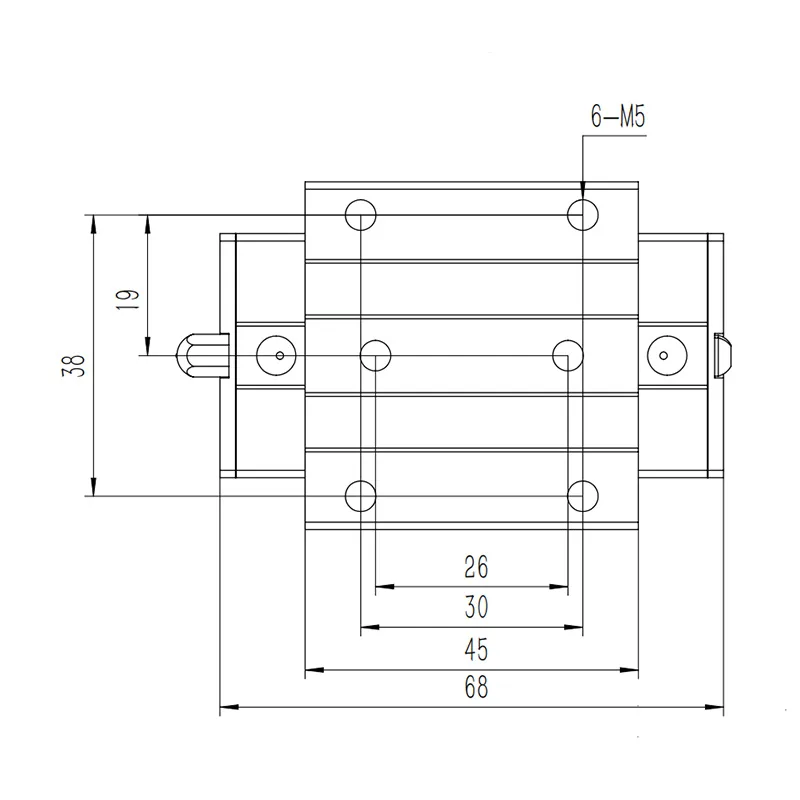

- Misure: 15, 20, 25, 30, 35, 45, 55, 65,85,100

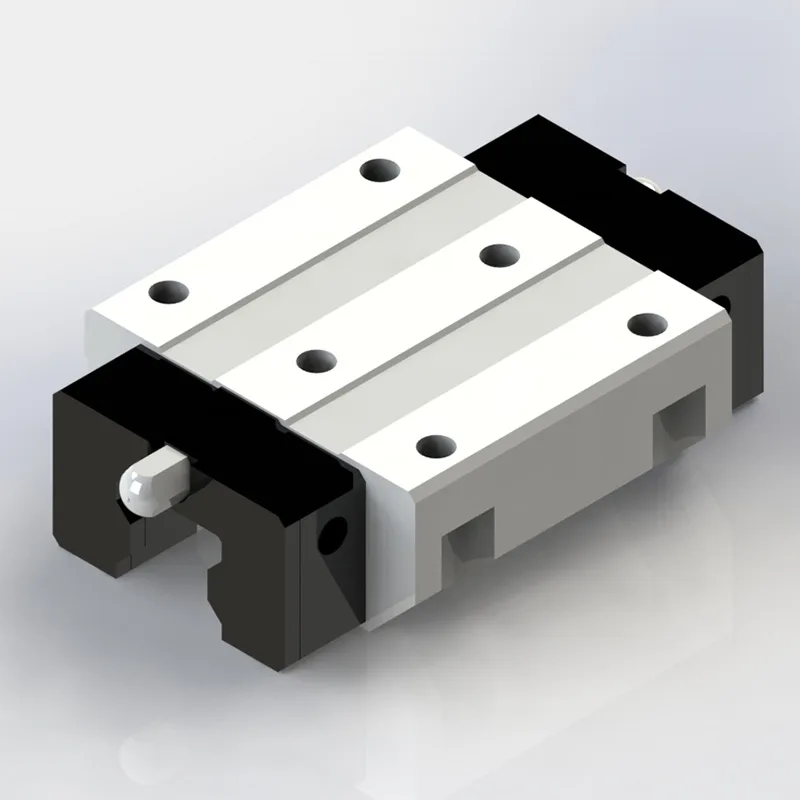

- Tipi di blocco: saure/flangia

- Gradi di precisione: C, H, P

- Materiale: Standard / Acciaio inossidabile

- Tipi di montaggio del blocco: montaggio superiore / montaggio inferiore

- Protezione dalla corrosione: cromatura dura, cromatura nera

- Livello di precarico: precarico leggero, precarico medio, precarico elevato

- Opzioni di protezione dalla polvere: 1.Raschiaolio + tenuta terminale + raschiatore metallico 2.Doppio raschiaolio + tenuta terminale + raschiatore metallico 3.Doppio raschiaolio + tenuta terminale

Perché scegliere il blocco lineare DTX-LG?

- Quantità minima d'ordine flessibile

- Prezzi competitivi

- Elevata personalizzazione

- Supporto e Servizio Professionale

- Garanzia di qualità

- Piena intercambiabilità

- Ottima scorrevolezza di marcia

- Vantaggio di costo significativo

01. Materiali ad Alta Resistenza

Le guide lineari per carichi pesanti DTX-LG sono realizzate in acciaio di prima qualità e sottoposte a trattamenti termici avanzati, raggiungendo una durezza superficiale di 59–62 HRC. Ciò garantisce un'eccezionale resistenza all'usura, una maggiore capacità di carico e una durata prolungata anche in condizioni di lavoro gravose.

Ogni guida lineare a rulli di precisione è dotata di sfere in acciaio di alta qualità temprate a 61–66 HRC. L'elevata durezza offre prestazioni di rotolamento eccezionali, migliora la distribuzione del carico e garantisce un movimento lineare fluido e preciso con attrito minimo.

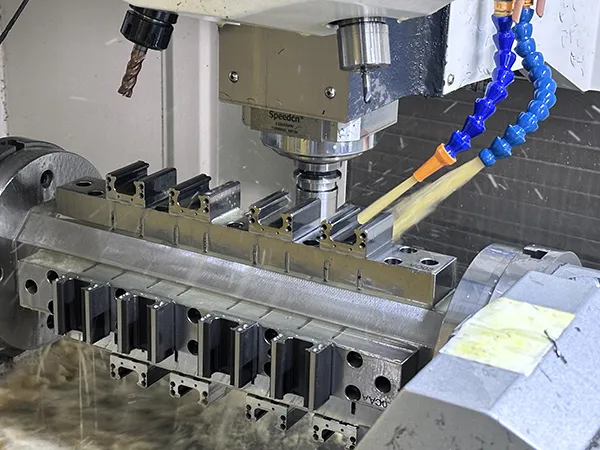

02. Progettato a Taiwan, prodotto in Cina

Ogni carrello resistente alla corrosione SGW è prodotto internamente con foratura e rettifica CNC per garantire precisione e uniformità. Con 16 linee di produzione e una produzione annua di 3.600.000 pezzi, DTX-LG garantisce un rigoroso controllo di qualità, forniture su larga scala e consegne affidabili in tutto il mondo.

03. Sistema Avanzato di Autolubrificazione

Un meccanismo di lubrificazione integrato è inserito nel cappuccio terminale, composto da un'unità di accumulo olio e un'unità di rilascio olio. L'elemento conduttore all'interno non solo assorbe e immagazzina l'olio, ma lo rilascia gradualmente sulla pista di rotolamento grazie alla sua struttura speciale. Questo design garantisce una lubrificazione continua, riduce significativamente le esigenze di manutenzione e mantiene il blocco funzionante in modo affidabile per lunghi periodi. Blocco lineare flangiato ideale per macchine CNC.

04. Garantire Pulizia e Affidabilità Prima del Montaggio

Ogni guida lineare verticale subisce un accurato processo di pulizia a ultrasuoni per rimuovere residui di lavorazione, particelle metalliche fini e impurità superficiali. Segue l'asciugatura ad aria calda per eliminare l'umidità e prevenire la corrosione. Solo dopo il completamento di queste fasi di pulizia e asciugatura, il blocco procede alla fase di assemblaggio, garantendo che ogni blocco SGH mantenga una superficie pulita e priva di contaminanti per un movimento fluido e un'affidabilità a lungo termine.

05. Sistema di Gestione Qualità ISO a Ciclo Completo

DTX-LG ha ottenuto multiple certificazioni ISO e implementa pienamente processi di gestione della qualità standardizzati ISO in ogni fase della produzione. Dall'ispezione delle materie prime e la lavorazione, all'assemblaggio e ai test finali, ogni passaggio segue rigorosamente le linee guida ISO. Ciò garantisce la coerenza del prodotto, la tracciabilità e la conformità agli standard di qualità internazionali, rafforzando il nostro impegno nel fornire assiemi di guide lineari e carrelli affidabili e riconosciuti a livello globale.

06. Incrementa le Tue Vendite: Distribuisci guide lineari a rulli

Per distributori e clienti OEM che cercano soluzioni competitive di cuscinetti per guide lineari a rulli, la serie SRW è una scelta economica e affidabile. La combinazione di elevata capacità di carico, design robusto e intercambiabilità la rende uno dei prodotti più versatili sul mercato.

I blocchi lineari a rulli flangiati DTX-LG SRW sono completamente intercambiabili con la serie RG di Hiwin e con i principali marchi come THK, TBI e IKO. Il design a flangia con fori di montaggio lavorati supporta l'installazione a montaggio inferiore. Il suo profilo basso e l'ampia superficie di supporto lo rendono ideale per applicazioni con grandi carichi di momento.

I carrelli della serie SR includono porte per olio sui lati e sulla parte superiore per una lubrificazione facile. Possono gestire carichi fino a 100 tonnellate, offrendo eccellente rigidità e stabilità per minimizzare la deformazione e le vibrazioni della macchina, garantendo un'elevata precisione di lavorazione.

Comunemente utilizzati nelle rettificatrici CNC e nei grandi centri di lavorazione a portale, i carrelli SRW sono affidabili per applicazioni di precisione e ad alto carico.

In qualità di produttore professionista di cuscinetti per guide lineari a rulli, DTX-LG fornisce trattamenti anticorrosione a cromo nero e cromo bianco, testati per 72 ore di resistenza alla nebbia salina per migliorare la durata in ambienti ostili.

Domande? Siamo a Vostra Disposizione

Di seguito sono riportate le domande frequenti poste dai distributori di guide lineari

01. Le carrelli a flangia SRW sono intercambiabili con altri marchi?

Sì. Il DTX-LG SRW è completamente intercambiabile con la guida lineare serie RG di Hiwin (RGW), nonché con i blocchi a flangia THK, TBI e IKO. Si tratta di una vera soluzione a rulli per guide lineari, che ne facilita la vendita come sostituto diretto.

02. Quali dimensioni di guide lineari a rulli sono in vendita?

DTX-LG offre una gamma completa che include SRW15, SRW25, SRW30, SRW35, SRW45, SRW55, SRW65, SRW85, SRW100. Ciò consente ai distributori di soddisfare con flessibilità le esigenze dei clienti alla ricerca di cuscinetti lineari a rulli per macchine utensili di diverse dimensioni.

03. Quali sono i principali vantaggi dei blocchi SRW rispetto ai blocchi SWH?

I carrelli lineari grandi SRW presentano una superficie di montaggio ampia, un'altezza di assemblaggio ridotta e un'eccellente capacità di carico di momento. Combinati con la progettazione della guida lineare a rulli, offrono rigidità molto elevata e movimento fluido, ideali per macchine CNC di precisione.

04. Quali tipi di macchine utilizzano i blocchi flangiati SRW?

Sono ampiamente utilizzati nelle rettificatrici a controllo numerico, nei grandi centri di lavorazione a portale e nelle applicazioni con carichi di momento elevati. Ciò li rende ideali per i distributori che servono gli OEM di macchine utensili e i mercati di retrofit.

05. Quanto carico può sopportare la serie SRW?

I blocchi a rulli della serie SR possono gestire carichi fino a 100 tonnellate. Ciò li rende adatti per clienti che necessitano di soluzioni di scorrimento lineare ad alto carico per applicazioni di taglio pesante o ad alta forza.

06. Come posiziono questo prodotto ai miei clienti?

Sottolineare i vantaggi competitivi del cuscinetto lineare a rulli, tra cui il prezzo vantaggioso, la completa intercambiabilità di marca, l'elevata rigidità e la lunga durata di servizio. Queste caratteristiche aiutano i clienti a ridurre i tempi di fermo macchina e i costi di manutenzione.

07. Quale supporto tecnico fornite?

Forniamo modelli CAD, diagrammi di carico, manuali di installazione e guide di lubrificazione per aiutare i distributori a promuovere e supportare efficacemente la serie SRW.

Vuoi un preventivo rapido?

Compila il modulo sottostante: il nostro ingegnere ti contatterà a breve in base alle informazioni fornite.