-

11/25/2025

- 0 Commentaire

6 erreurs à éviter lors de l’achat de guides linéaires alternatifs à Hiwin

With the rising demand for linear guides, many buyers look for cost-effective alternatives to Hiwin. A good replacement can save 20–40% of the cost without sacrificing performance—but only if you choose correctly.

Unfortunately, many users fall into the same traps. Here are the 6 most common mistakes and how to avoid them.

The good news is: you are not alone, and viable solutions for your linear motion needs do exist. The key to successfully replacing the HIWIN series with a budget-friendly brand lies in understanding the true meaning of “interchangeability” and avoiding common pitfalls. This guide, based on practical experience, will provide you with a clear, in-depth roadmap.

Are there any brand could replaced HIWIN HG/EG with an alternative brand?

Yes, but careful discernment is required.

As an industry leader, HIWIN’s EGR Series (which belongs to the miniature ball linear guide family) is widely used due to its compact size and high rigidity. Several major brands on the market offer competing product lines that strive for interchangeability in mounting dimensions. This means:

- Same Hole Positions: The spacing and size of the mounting screw holes are consistent with the HG/SG Series.

- Similar Profile: The width and height of the rail are nearly identical, allowing for smooth installation onto existing machine bases.

- Matched Block Interface: The flange size and screw hole positions of the block are compatible with the HG/SG Series, enabling direct replacement of the old block.

These design goals make “direct replacement” physically possible. Based on market feedback and project experience, the following brands perform well in terms of cost-effectiveness and interchangeability:

| Category | Marque | Advantages | Precautions |

Original manufacturer | Brand consistency with a reliable supply chain. | Still high-end, with limited price drops. | |

Top-tier competitor | Top-tier performance with unquestionable reliability. | Still pricey and may require special-channel quotes. | |

High quality | A reputable Japanese brand with overlapping dimensions/specifications. | Double-check the dimensions for each model. | |

Cost-effective | DTX-LG…. | Significantly reduced cost with strong market validation. | Pay close attention to preload, accuracy, and coating. |

The safest approach is to obtain the specific model of the HIWIN HG/EG series you are currently using (e.g., HG15 CA), and then directly request a “cross-reference table” or “interchangeable model list” from the linear guide suppliers or distributors of these alternative brands.

DTX-LG is one of the main sources for cost reduction. As a manufacturer with 35 years of industry experience and 5 years of linear guide manufacturing experience, its product catalog clearly marks the models that are interchangeable with the HIWIN EGR Series. For your convenience in checking compatibility, DTX-LG can provide 3D models and 2D parameters of the linear guides.

Anything should watch out for when using non-HIWIN linear rails and block?

Matching the physical dimensions is only the first step. There are 6 erreurs à éviter lors de l’achat de guides linéaires alternatifs à Hiwin, especially the following points for CNC machine tool applications:

1.Choosing the wrong preload and rigidity

This is the biggest risk factor. HIWIN linear bearing blocks have different preload classes (e.g., C0 Light Preload, C1 Medium Preload).

CNC linear guide rails Application Recommendation:

For CNC machine tools, Medium or Heavy Preload is the safer choice to ensure sufficient rigidity to withstand cutting forces. Standard replacement parts are often Light Preload (or C0, No Preload), which can lead to insufficient machine rigidity, resulting in shaking or chatter during machining, thus affecting surface finish quality.

It is crucial to clearly specify the required preload class when ordering (e.g., P3 Medium Preload).

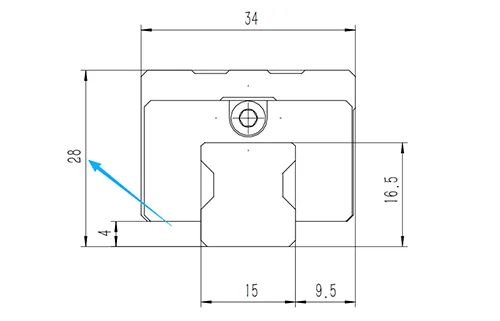

2.Ignoring the Stack Height Tolerance(linear rail and block)

Not considering mounting surface errors, rail machining tolerances, and total combined deviation.

The tolerance of the Stack Height (the total height from the bottom surface of the rail to the mounting surface of the block) is crucial for the parallelism of a multi-guide rail system.

Key Difference: The stack height tolerance for standard guide rails can be as high as 0.03mm (0.004 inch), which is absolutely unacceptable for high-precision CNC machine tools.

Action Required: When ordering, you must specify a high-precision tolerance grade (e.g., 0.02 ) to ensure consistent height across all rail and block combinations, preventing mounting stress or positioning errors after installation.

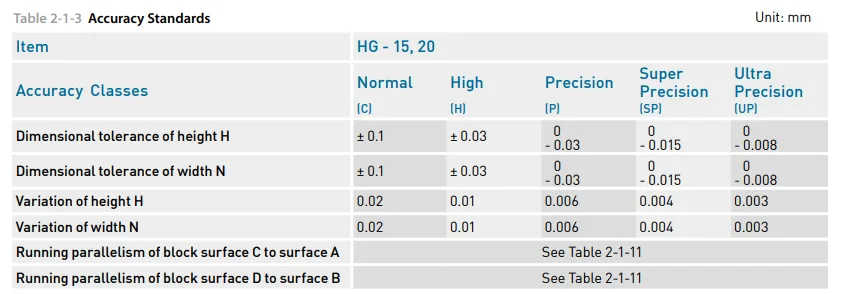

3.Selecting an incorrect accuracy grade

Cusing a lower accuracy level even though the application requires high positioning or repeatability.

Linear guide rails and block typically have 12 or more Accuracy Standards (such as Normal Grade C, High Grade H, Precision Grade P, etc.). Although they all claim to be “Normal Grade” or “High Grade,” the precision standards can vary subtly between different brands.

For most CNC machine retrofits, it is recommended to select at least the High Grade (H) or higher to ensure smooth operation and accurate positioning.

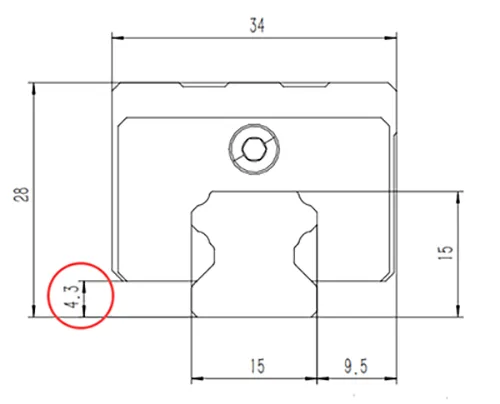

4.Overlooking bottom of block to bottom of rail dimension

Leading to poor installation stability, uneven stress, and reduced lifespan.

This point is often overlooked, but it is extremely important.

- Key Difference: Although the flange and hole dimensions may be the same, the specific dimension from the bottom of the block to the bottom of the rail (often the mounting datum point) can have minor variations between different manufacturers. If this dimension is inconsistent, it may affect the installation or alignment of your existing accessories (such as bellows covers or clamps).

- Action RequiredAvant l'achat, vous devez demander les plans d'ingénierie détaillés du produit alternatif et les comparer aux plans du rail et du bloc HIWIN d'origine.

5.Négligence de prendre en compte les exigences de revêtement et de résistance à la corrosion

Provoquant la rouille ou une défaillance prématurée dans les environnements humides, l'exposition au liquide de refroidissement, la poussière ou les utilisations en extérieur.

Dans un environnement d'atelier d'usinage CNC, le revêtement (traitement de surface) est extrêmement important.

- Chrome Noir HIWIN : Offre une excellente résistance à la rouille, à l'usure et aux rayures, et il est plus propice à la formation d'un film d'huile pour une meilleure lubrification.

- Alternatives à Bas Coût : Peuvent utiliser la galvanisation standard ou un placage ordinaire avec des capacités anti-corrosion plus faibles.

Ne sacrifiez pas le traitement de surface pour économiser un faible coût. Pour les applications CNC, nous recommandons fortement de choisir des alternatives comportant un chrome noir de haute qualité ou un revêtement aux performances équivalentes (tel que la phosphatation) pour prolonger la durée de vie et la stabilité du système.

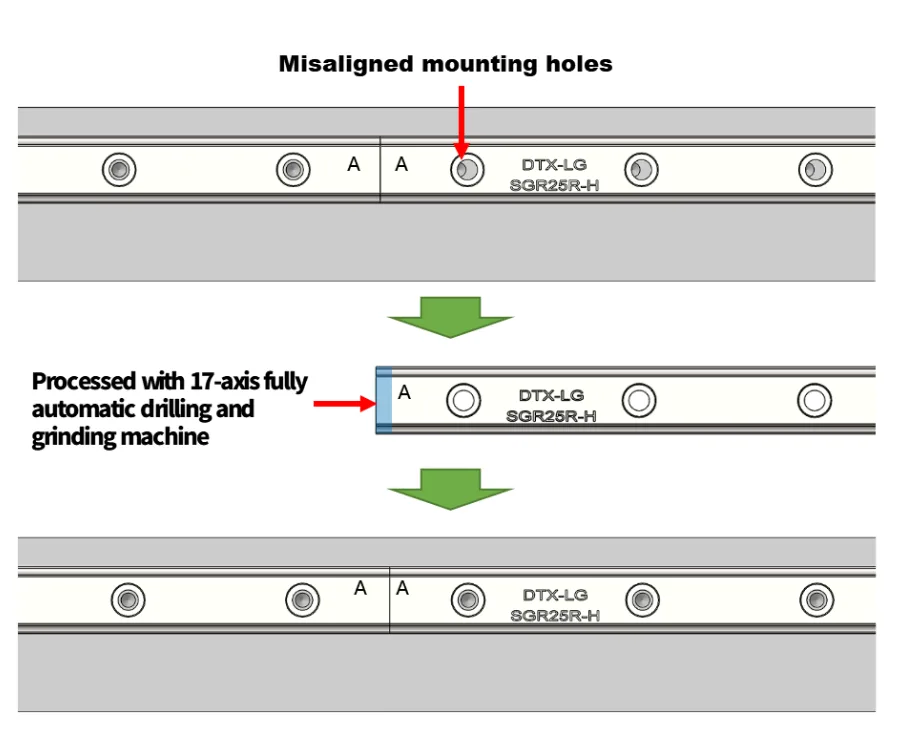

Ignorer l'alignement des joints et le contrôle du jeu entre rails

Entraînant un mouvement brutal, un bruit plus élevé et une précision de positionnement réduite.

Les longs rails guides sont généralement fournis en sections. Les kits de jointure et les conceptions d'interface pour connecter les rails varient selon les différentes marques. Une mauvaise manipulation peut provoquer un saut ou un déplacement notable au niveau des joints, affectant la précision d'usinage.

Action Requise : Pendant l'installation, veuillez strictement suivre le manuel d'instructions de la marque alternative pour l'assemblage et l'alignement.

Effectuer un Test d'Échantillon : Si le projet le permet, achetez d'abord un ensemble (un rail et un patin) pour testing. Mesurez manuellement les dimensions, vérifiez la finition et effectuez des tests à vide et à charge légère sur la machine.

Choisir des Marques Alternatives Réputées : Privilégiez des fabricants de rails linéaires établis et réputés comme DTX-LG et PMI, plutôt que des produits de commerçants totalement inconnus. Ils offrent un contrôle qualité et un support après-vente plus complets.

Communiquer avec un fournisseur fiable : Trouvez une entreprise professionnelle et sérieuse spécialisée dans les guides linéaires, informez-la clairement de votre application (petite CNC), de la marque d'origine (par exemple, HIWIN EGR25, HIWIN HG25CC), ainsi que de vos exigences concernant la précharge (moyenne à élevée) et la tolérance de hauteur d'empilement (haute précision). Demandez également qu'elle fournisse des modèles 3D.

Grâce à une sélection et des tests minutieux, vous pouvez réduire considérablement les coûts des pièces de rechange du projet sans sacrifier les performances de la machine, réalisant ainsi une situation gagnant-gagnant pour le client et le projet.

DTX-LG, en tant que leader parmi les fournisseurs de guidages linéaires, propose des produits entièrement interchangeables avec les séries HIWIN HG et EG.