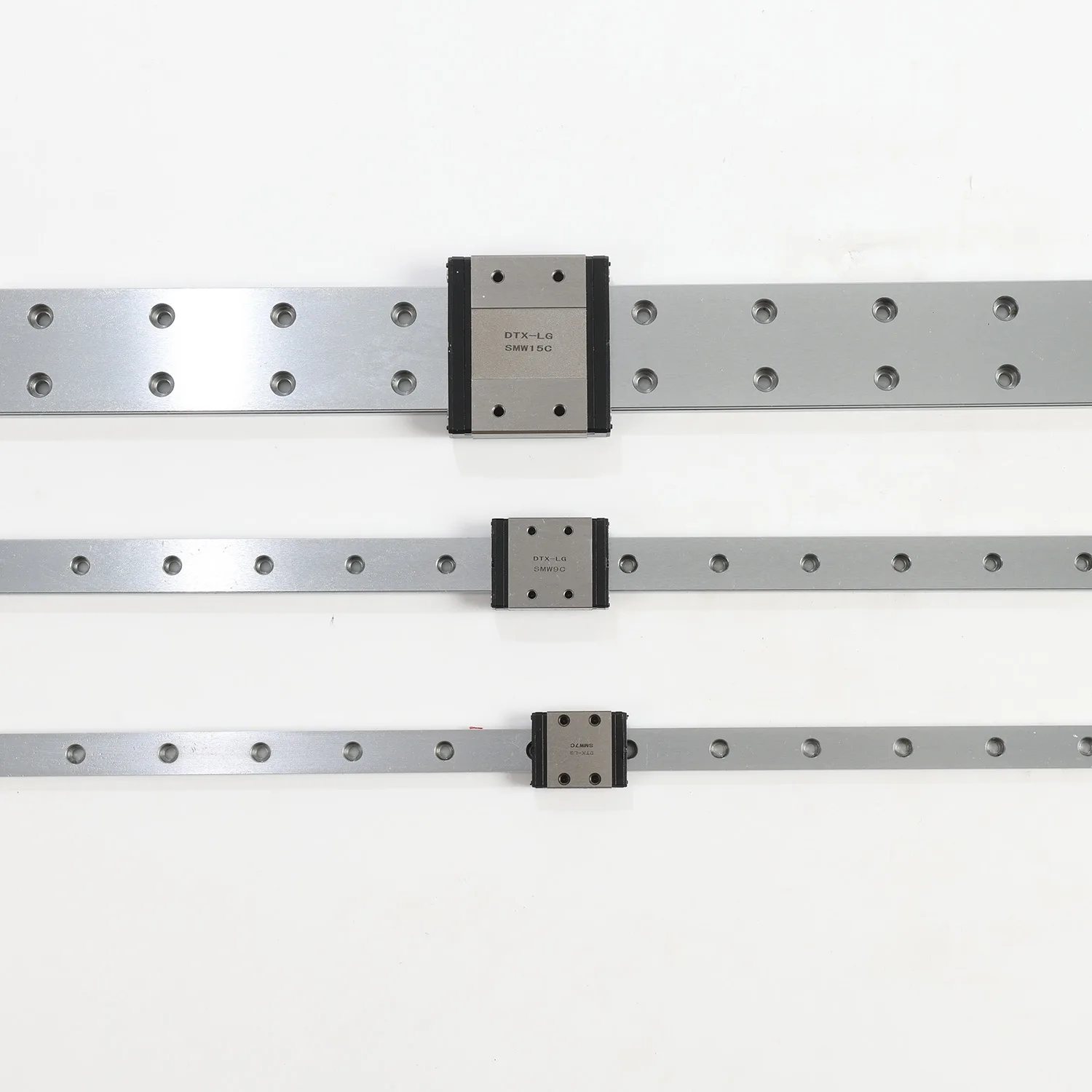

Breites Führungsset

SMW 5/7/9/12/15

Hiwin mgw series interchangeable linear guides and rails

- Rail length: up to 6 m

- Block types: Standard / extended

- Accuracy grades: C, H, P,

- Sizes: 5, 7, 9, 12, 15

- Block mounting types: Obere Montage / Untere Montage / Obere oder untere Montage

- Material options: stainless steel, black chrome plated, hard chrome plated

Why DTX-LG linear Block?

- Flexible MOQ (Mindestbestellmenge)

- Wettbewerbsfähiger Preis

- Hohe Individualisierbarkeit

- Professionelle Unterstützung & Service

- Qualitätssicherung

- Vollständige Austauschbarkeit

- Good running smoothness

- Significant Cost Advantage

01. High-Strength Materials

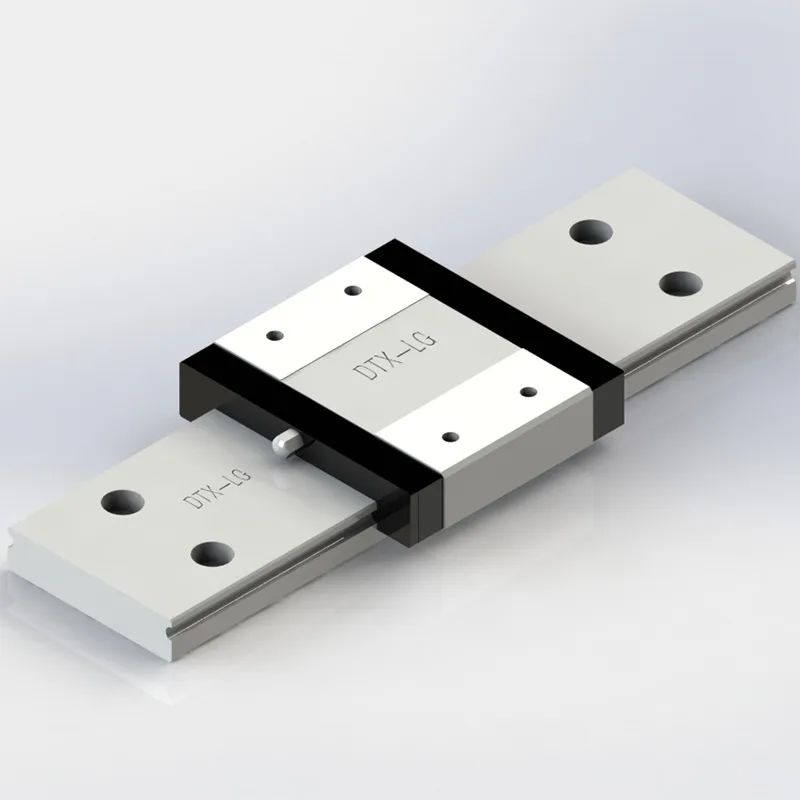

DTX-LG linear guide rail and carriage is manufactured from premium steel and undergoes advanced heat treatment, achieving a surface hardness of 59–62 HRC. This ensures excellent wear resistance, higher load capacity, and extended service life even under heavy-duty conditions.

Each precision flanged linear block is equipped with high-quality steel balls hardened to 61–66 HRC. The superior hardness provides outstanding rolling performance, enhances load distribution, and guarantees smooth, precise linear motion with minimal friction.

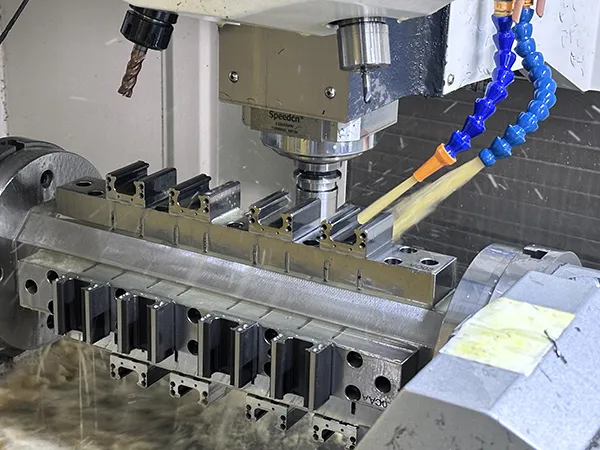

02. Design in Taiwan, made in china

Each good quality wide rail linear guideway is manufactured in-house with CNC drilling and grinding to ensure accuracy and consistency. With 16 production lines and an annual output of 3,600,000 pieces, DTX-LG guarantees strict quality control, large-scale supply, and reliable delivery worldwide.

03. Advanced Self-Lubrication System

A built-in lubrication mechanism is integrated into the end cap, consisting of an oil storage unit and an oil release unit. The oil guide element inside not only absorbs and stores oil but also gradually releases it to the raceway through its special structure. This design ensures continuous lubrication, significantly reduces maintenance requirements, and keeps the block running reliably over long periods. Idea flanged linear block for CNC machine.

04. Ensuring Cleanliness and Reliability Before Assembly

Each linear rail guide with bearing block undergoes a thorough ultrasonic cleaning process to remove machining residues, fine metal particles, and surface impurities. This is followed by hot air drying to eliminate moisture and prevent corrosion. Only after these cleaning and drying steps are completed does the block proceed to the assembly stage, ensuring that every linear motion components maintains a clean, contaminant-free surface for smooth motion and long-term reliability.

05. A Full-Cycle ISO Quality Management System

DTX-LG has obtained multiple ISO certifications and fully implements standardized ISO quality assurance management processes across every stage of production. From raw material inspection and machining to assembly and final testing, each step strictly follows ISO guidelines. This ensures product consistency, traceability, and compliance with international quality standards, reinforcing our commitment to delivering reliable and globally recognized linear guide rail & carriage assemblies.

The DTX-LG wide miniature linear guideways are dimensionally compatible with the Hiwin MGW series. When loads are applied off-center or with a cantilever, they create a moment force that tends to tip the block. Standard narrow miniature guides often suffer significant accuracy loss or even damage under such conditions.

Thanks to its wide linear guide design, the DTX-LG wide series provides a much larger support surface, allowing it to easily withstand high overturning moments. These wide low profile linear rails are an excellent choice for applications such as large industrial robot joints and arms, vertical machining center tool turrets, gantries on laser cutting machines, and precision inspection modules carrying heavy sensors.

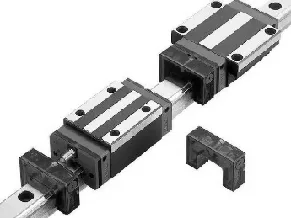

The standardized design ensures full interchangeability with THK, IKO, HIWIN, TBI, and PMI equivalents, making replacement simple and cost-effective.

As a professional supplier of linear guide – short and wide block products, DTX-LG offers not only standard steel components but also a variety of surface treatments, including black chrome plating, hard chrome plating, and anti-corrosion coatings. These treatments improve wear resistance, reduce noise, and prevent reflection, making DTX-LG a trusted wholesale linear motion guide block and linear bearing block solution for high-end precision equipment manufacturers.

Fragen? Wir sind für Sie da

As a linear guide assembly manufacturer, DTX-LG offers professional service from R&D and production to final adjustment. We look forward to exploring new challenges with you.

01. Why choose wide low profile linear rails over standard miniature linear guideways?

Wide rails provide larger support surfaces and resist overturning moments, preventing accuracy loss when loads are off-center.

02.What applications are ideal for this type of linear guide – short and wide block?

They are perfect for large industrial robot joints, laser cutting machine gantries, vertical machining center turrets, and precision inspection modules.

03. Do you supply wholesale linear motion guide blocks for OEM projects?

Yes. DTX-LG specialize in bulk supply for distributors and OEMs, with consistent quality and competitive pricing.

04. How do your wide linear guides perform under heavy loads?

The increased rail width and block support significantly improve rigidity and allow higher load and moment capacities.

05. Do you provide CAD models and technical drawings?

Yes. DTX-LG supply full 2D/3D drawings for easy integration into your machine design.

06. What is the lead time for wide low profile linear rails?

DTX-LG maintain stock of standard sizes and offer fast production and shipping for custom orders.

Broschüren herunterladen

Möchten Sie ein unverbindliches Angebot?

Bitte füllen Sie das untenstehende Formular aus – unser Ingenieur wird Sie zeitnah auf Basis Ihrer Angaben kontaktieren.