-

01/06/2026

- 0 Kommentar

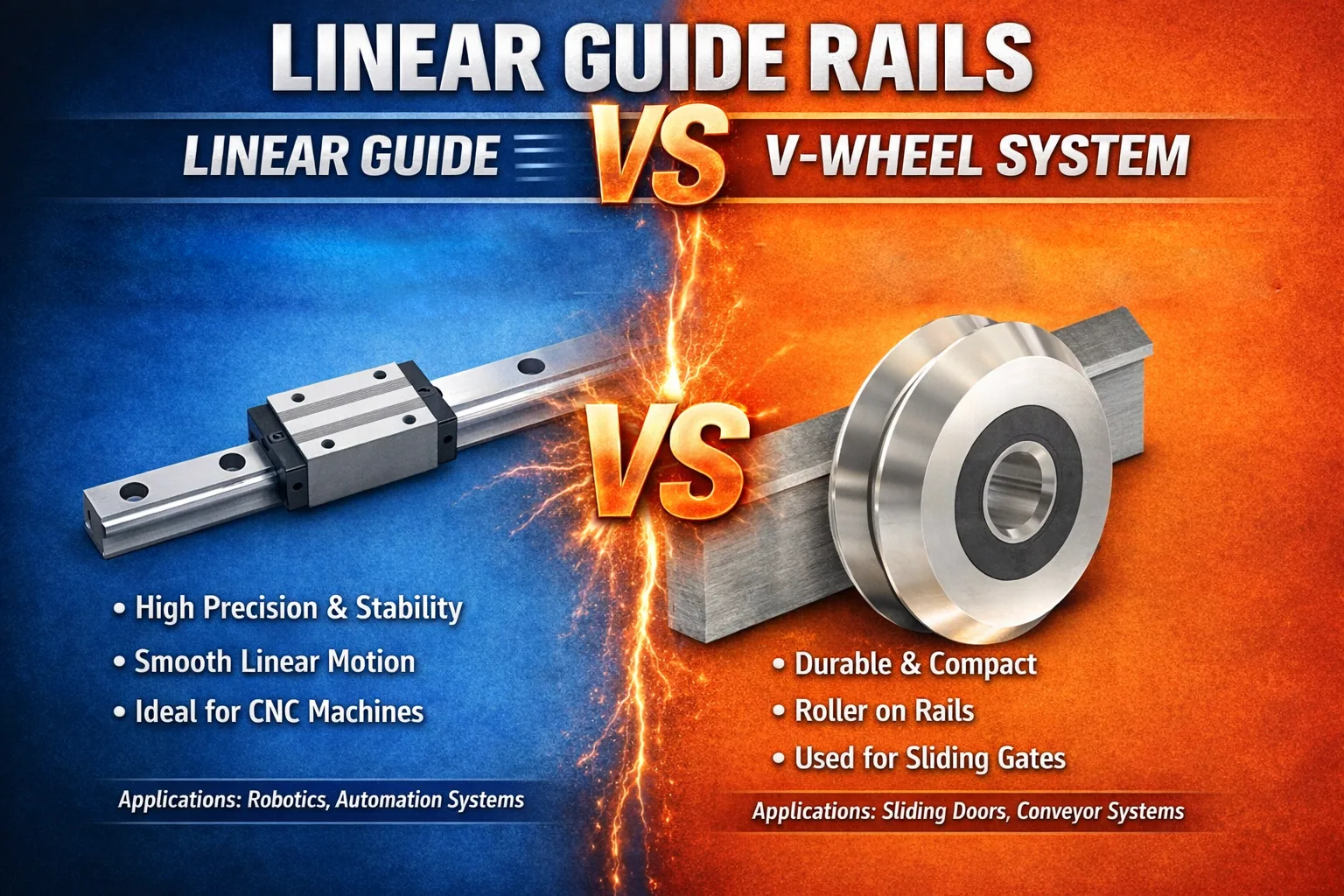

Linearführungen im Vergleich zu V-Rollen

In the design of automation equipment and precision machinery, the selection of a linear motion system is critical. From an engineer’s perspective, this article provides an in-depth comparison between linear guides and V-shaped roller systems across key dimensions such as definition, structure, materials, application scenarios, and overall cost, helping engineers make informed choices.

Definition of V Wheels & Linear Rails

what is a linear rail guide?

A profiled linear guide is a linear motion system where rolling elements—balls or rollers—circulate along precision-ground tracks and a ball carriage. Its core components include the linear guide rail, ball carriage, rolling elements, recirculation system, and end-cap seals. Multi-row raceways provide four- or multi-point contact, essentially linearizing the principle of a rotary bearing to deliver near-zero backlash, high rigidity, and micron-level accuracy. Engineers often ask, “what is a linear guide rail used for?”—it provides precise, stable motion for CNC machines, laser systems, metrology equipment, and other applications requiring high repeatability.

What is v wheels

A V-groove system consists of V-profile wheels and matching V-shaped rails. Wheels are typically mounted on moving parts via eccentric shafts or bearing housings and roll along the V-profile surfaces. The “V” contact angle offers self-aligning capability, allowing preload adjustments to compensate for installation errors or wear, providing high adaptability in less-controlled environments.

Currently well-known V-wheels brands include: PBC, Rollon, MISUMI, etc.

Material difference between v groove rails & linear guide rail set

What Materials Make wheel guide rail?

V-Wheel rails often use high-carbon steel (e.g., 1045) with surface hardening, or stainless steel (e.g., 304) for corrosion resistance. Wheels may be bearing steel (GCr15), engineering plastics (PU, POM), or coated, depending on load, noise, and environmental requirements.

What Materials Make rail and carriage?

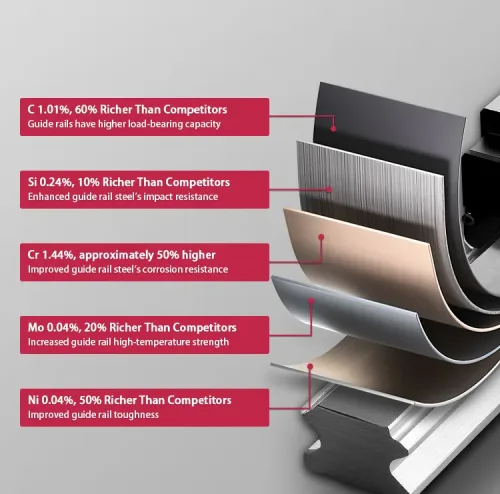

Standard Linear Guides typically made from high-carbon chromium bearing steel (e.g., SUJ2/GCr15) with through-hardening for balanced mechanical properties.

DTX-LG as linear rail maker produces products that exceed the performance of standard bearing steel.

Enhanced Carbon Content: Optimized within controlled limits to increase post-heat-treatment hardness, boosting compressive strength and wear resistance.

Alloying with Nickel (Ni): Improves hardenability and toughness, ensuring a smoother hardness gradient from surface to core. High surface hardness (HRC 58–62+) is achieved without sacrificing core toughness, resisting impact loads and brittle fracture.

This “hard surface + tough core” philosophy ensures DTX-LG linear guide rail sets maintain precision and durability under heavy loads, high speeds, and continuous operation—perfect for linear rail Z-axis applications in gantry systems or other vertical motion stages.

Application scenario comparison

| Scenario | Recommended Solution | Core Reasoning |

|---|---|---|

| High precision, high rigidity (CNC machines, laser cutting, metrology) | DTX-LG linear guides | Multi-point contact, ultra-rigid structure, micron-level accuracy, excellent dynamic response. Ensures Z-axis stability and precision. |

| Harsh environments (dust, wood chips, humidity, outdoor) | V-Groove Systems | Self-cleaning V-angle, corrosion-resistant materials, adaptable to contamination. |

| Heavy load, high torque (gantry Z-axis, heavy handling) | DTX-LG Heavy-Duty Linear Guides | Roller-based design with large contact area, supporting multi-directional heavy loads and overturning moments. |

| Poor installation surfaces, flexible adjustment needed (large welded structures, custom automation lines) | V-Groove Systems | Low flatness requirement; preload and gap easily adjusted on-site. |

| High-speed, quiet operation (precision electronics, medical equipment) | DTX-LG Silent Linear Guides | Optimized raceway and ball carriage design for smooth, low-noise motion with excellent sealing. |

| Cost-sensitive, light load, medium/low speed (light conveyors, warehouse systems) | V-Groove Systems | Lower initial cost and installation effort, sufficient for basic motion needs. |

Total Cost comparison

Engineers must consider total cost of ownership.

Initial Component Cost:

V-Groove: Individual components may be cheaper but must be purchased as a complete set.

DTX-LG linear guide rail set: Higher upfront cost, reflecting built-in high performance, accuracy, and reliability.

Installation & Commissioning:

V-Groove: Flexible, lower precision requirement, saving machining and assembly hours.

DTX-LG: Demands precise installation (flatness, parallelism), but once installed, delivers long-term, stable performance with minimal adjustments. Full technical guidance is provided to optimize installation.

Maintenance & Lifecycle:

V-Groove: Simple but frequent; wheels are wear items, easily replaced. Rails last longer.

DTX-LG: Long maintenance intervals, high lifecycle reliability. Optimized materials and manufacturing translate to extended maintenance-free operation and higher equipment uptime.

Conclusion & DTX-LG Value Proposition

Choosing V-Groove Wheels means prioritizing flexibility and environmental adaptability—a clever solution for cost-conscious or complex setups.

Choosing DTX-LG profiled linear guides is about certainty and performance ceiling. It’s an investment in precision, speed, rigidity, and long-term operational stability. Optimized core materials (high-carbon, high-nickel bearing steel), precision manufacturing (fully closed-loop grinding), and stringent quality control make every DTX-LG linear guide rail set a reliable “skeleton” for your machinery.

For Engineers:

When your design demands uncompromising motion performance, DTX-LG guides aren’t just a spec—they are your partner in eliminating performance risk and ensuring your design intent, from X/Y stages to linear rail Z-axis applications, is fully realized.

Contact DTX-LG technical team today to receive tailored material reports and selection guidance for your specific application, and let’s build machinery that’s more precise, reliable, and future-proof.