DTX-LG Roller Linear Guides

SR SERIES

Heavy Load Roller Linear rail CNC

The DTX-LG SR series linear gantry guide features roller-type rolling elements (replacing steel balls) to deliver ultra-high rigidity and heavy load linear guides capacity. Leveraging line contact between rollers, rail, and block, it minimizes elastic deformation under extreme loads. With a 45-degree contact angle, the guide achieves uniform rigidity and load capacity in all four directions. This ultra-rigid design enhances machining accuracy for CNC linear guides, meeting stringent precision demands. Its exceptional heavy-load performance extends service life, making the SR series ideal for high-speed automation machinery and linear rails CNC applications requiring uncompromised rigidity. This linear guide is fully interchangeable with THK SRG and linear guideway HIWIN RG series, offering similar precision and performance at a more competitive cost.

heavy duty linear slide rails SGR

Havy duty linear Guide unit

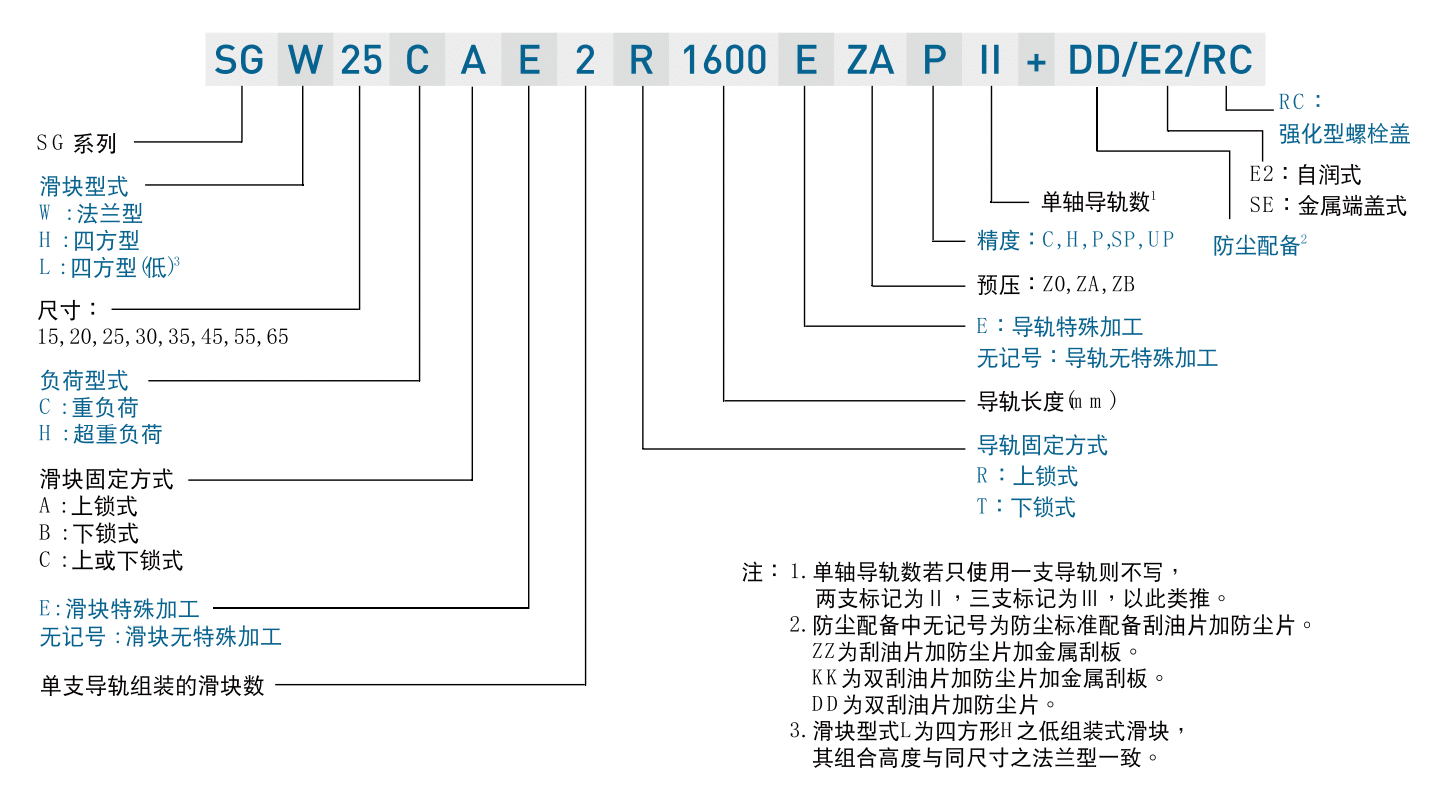

Order Of linear guide rail systems

Free Samples Available!

We’re glad to provide you with free samples. You can choose to pay for shipping either upon receipt or in advance. Just let us know what you need, and we’ll ensure your satisfaction before you make a purchase.

Why Choose DTX-LG as Your Linear Guides Manufacturer?

The SR series linear guides replace balls with rollers, utilizing line contact between rollers, rails, and sliders. This design significantly enhances rigidity and load capacity while maintaining high machining precision.

The accuracy of the SG series linear guides is divided into five levels: ordinary, high, precision, ultra-precision and ultra-high precision. Customers can choose the accuracy according to the accuracy requirements of the equipment.

DTX-LG linear guides feature excellent dimensional accuracy and standardized design, ensuring high interchangeability. They can directly replace major brands like THK and HIWIN, offering a cost-effective alternative.

DTX-LG provides two types of linear guides: flange type and square type. The square type linear guide is divided into H type and L type. The L type is a low-assembly linear guide of the H type, and its combined height is the same as that of the flange type linear guide.

DTX-LG provides two types of linear guides: flange type and square type. The square type linear guide is divided into H type and L type. The L type is a low-assembly linear guide of the H type, and its combined height is the same as that of the flange type linear guide.

Certificates and Patents

DTX-LG linear guide come with a host of certifications—functional and design patents, ISO 9001, ISO 13485, ISO 45001, ISO 14001, virus & bacterial filtration tests, and more. We continually add credentials to ensure quality.

Questions? You’re covered

As a manufacturer of linear guide rails, DTX-LG offers professional service from R&D and production to final adjustment. We look forward to exploring new challenges with you.

01. What is a roller type linear guide and how does it work?

A roller-type linear guide uses cylindrical rollers instead of balls to facilitate linear motion. The rollers roll along the raceways, providing higher load capacity and rigidity compared to ball-type guides.

02. What are the main advantages of roller-type linear guides?

They offer superior load capacity, higher rigidity, better resistance to shock and vibration, and longer service life under heavy-duty conditions.

03. How do roller-type guides differ from ball-type guides?

Roller guides have cylindrical rolling elements that support heavier loads and provide greater stiffness, while ball guides excel in lower friction and higher speed but with lower load capacity.

04. What maintenance do roller-type linear guides require?

Regular lubrication is essential to maintain smooth operation and extend lifespan. Some models include grease fittings for easier maintenance.

05. How do I choose the right roller-type linear guide for my application?

Consider load capacity, rigidity requirements, operating speed, environmental factors, and installation dimensions. Our engineering team can help with tailored recommendations.

Want a quick quote?

Receive requests and quotations

*No model? Just share dimensions or usage—we’ll recommend one.

*Get a quote based on your specs: model, size, quantity, etc.

Confirm samples

* All samples are securely packed to ensure they arrive in good condition.

Production on demand

*Our production follows ISO standards to ensure precision and consistency.

Delivery and suppoet

*Multiple shipping options are available: sea, air, or express (DHL/UPS/FedEx).

Want a quick quote?

Please fill out the form below — our engineer will contact you shortly based on the information you provide.