DTX-LG Heavy Duty Linear Guides

SG SERIES

Heavy Duty Linear Guides

DTX-LG heavy duty linear rail system delivers robust performance as a direct, dimensionally identical replacement for HIWIN HG series guides. This high-capacity linear guide rail heavy duty solution offers proven rigidity, exceptional load ratings, and extended durability—perfect for demanding applications like CNC machinery, automation, and material handling where reliable motion under stress is critical. Choose our heavy duty linear guide for a cost-effective, seamless upgrade path that maintains HIWIN HG compatibility while optimizing value.

heavy duty linear slide rails SGR

Havy duty linear Guide unit

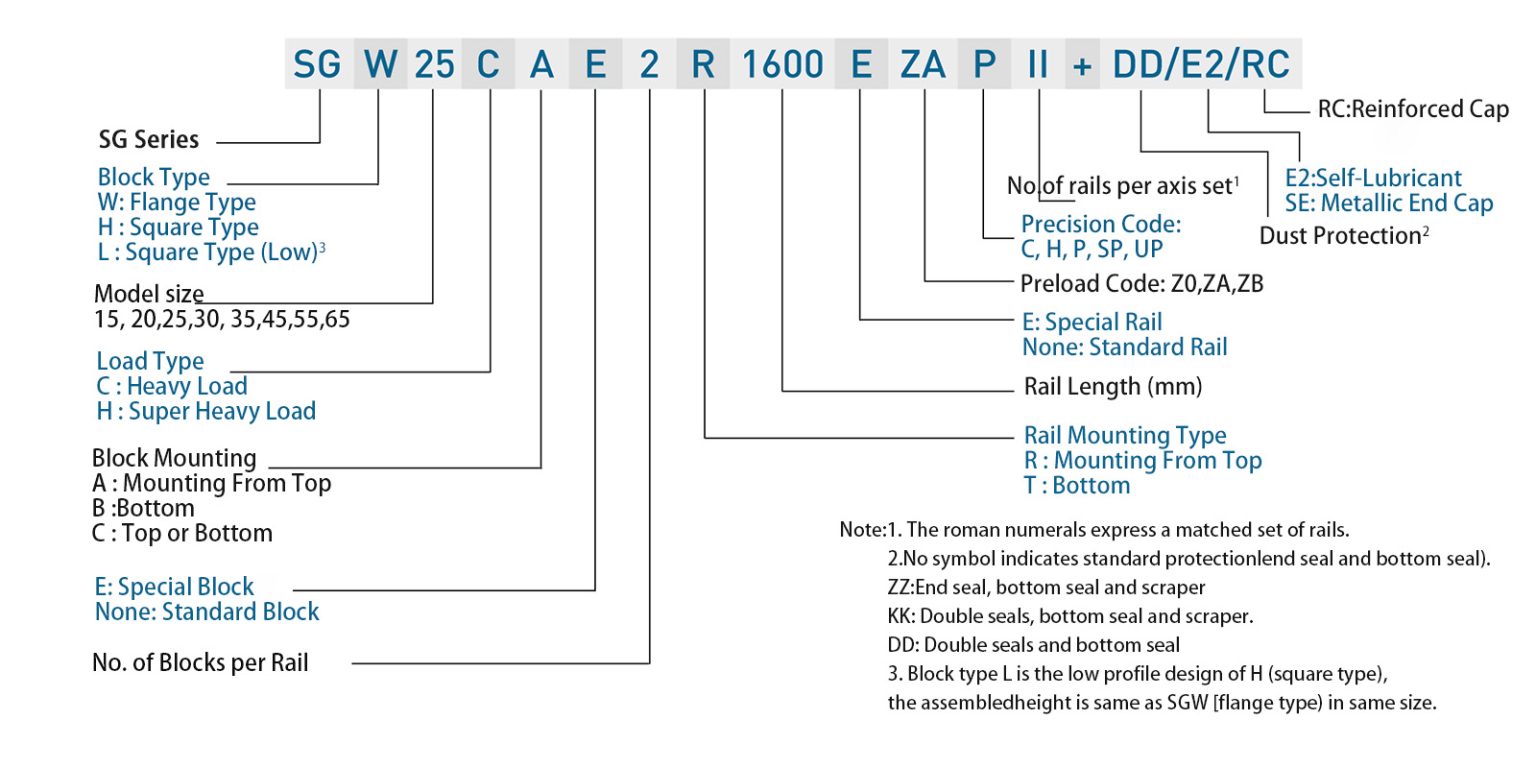

Order Of Heavy Duty Linear Guides

Free Samples Available!

We’re glad to provide you with free samples. You can choose to pay for shipping either upon receipt or in advance. Just let us know what you need, and we’ll ensure your satisfaction before you make a purchase.

Why Choose DTX-LG as Your Linear Guide Manufacturer?

DTX-LG develops dustproof accessories with enhanced high dustproof function for working environments that are more stringent than general environments. If you need the following high dustproof accessories, please add the code after the product model.

The accuracy of the SG series linear guides is divided into five levels: ordinary, high, precision, ultra-precision and ultra-high precision. Customers can choose the accuracy according to the accuracy requirements of the equipment.

DTX-LG linear guides feature excellent dimensional accuracy and standardized design, ensuring high interchangeability. They can directly replace major brands like THK and HIWIN, offering a cost-effective alternative.

DTX-LG provides two types of linear guides: flange type and square type. The square type linear guide is divided into H type and L type. The L type is a low-assembly linear guide of the H type, and its combined height is the same as that of the flange type linear guide.

DTX-LG provides two types of linear guides: flange type and square type. The square type linear guide is divided into H type and L type. The L type is a low-assembly linear guide of the H type, and its combined height is the same as that of the flange type linear guide.

Certificates and Patents

DTX-LG linear guide come with a host of certifications—functional and design patents, ISO 9001, ISO 13485, ISO 45001, ISO 14001, virus & bacterial filtration tests, and more. We continually add credentials to ensure quality.

Questions? You’re covered

As a manufacturer of linear guide rails, DTX-LG offers professional service from R&D and production to final adjustment. We look forward to exploring new challenges with you.

01. What materials and hardening processes are used for the raceways and balls?

Our guides use high-carbon chromium bearing steel for the raceways and balls. Raceways undergo precision grinding and induction hardening to achieve surface hardness (typically HRC 58~62) and depth comparable to leading brands like HIWIN HG, ensuring durability and long service life.

02. What preload levels are heavy duty linear rails for sale?

DTX-LG heavy duty linear track system offer standard preload options (e.g., C0, C1, C2) matching the HIWIN HG series specifications, allowing you to select the optimal rigidity and smoothness for your application’s precision requirements.

03. Can I use your carriages with HIWIN HG rails (or vice versa)?

While dimensions are identical, we strongly recommend using our heavy duty linear rail systems carriages with our matching rails to guarantee optimal performance, preload, longevity, and warranty coverage. Mixing brands can lead to unpredictable performance and premature wear

04. Do you offer corrosion-resistant options?

Yes, heavy duty linear motion guide rails offer models with surface treatments like black oxide coating or alternative options providing enhanced corrosion resistance comparable to HIWIN HG’s stainless steel or coated variants. Check specifications for specific corrosion protection details.

05. Why should I choose your guides over HIWIN HG?

Our linear rails heavy duty deliver identical performance, durability, and dimensional compatibility to the HIWIN HG series. You benefit from potentially shorter lead times, more responsive technical support, and competitive pricing without compromising on quality or reliability for your critical applications.

Want a quick quote?

Receive requests and quotations

*No model? Just share dimensions or usage—we’ll recommend one.

*Get a quote based on your specs: model, size, quantity, etc.

Confirm samples

* All samples are securely packed to ensure they arrive in good condition.

Production on demand

*Our production follows ISO standards to ensure precision and consistency.

Delivery and suppoet

*Multiple shipping options are available: sea, air, or express (DHL/UPS/FedEx).

Want a quick quote?

Please fill out the form below — our engineer will contact you shortly based on the information you provide.