CNC linear guides

Industries

- CNC linear guides

- Medical linear guides

- Semiconductor linear guide

- Matrial forming linear guide

- Printer linear guide

- Robotics linear guide

CNC linear guides application

As core equipment for high-precision and efficient manufacturing, CNC machine tools’ performance fundamentally depends on critical motion components. Linear rails for cnc, utilizing rolling friction designs (ball linear guide or roller type linear guide), achieve micron-level positioning accuracy and exceptional repeatability through precision raceway geometry and preloading. Their multi-directional rigidity effectively withstands cutting forces, gravitational loads, and inertial forces during acceleration/deceleration, ensuring machining stability and vibration resistance.

- High Positioning Precision

- Extended Service Life

- High Operational Speed

- Contamination Resistance

- Compact Design

- Low Total Cost of Ownership

Horizontal machining center

Linear guide rail and blocks for CNC machine offer significant advantages in horizontal machining centers. They provide robust rigidity and high load capacity, essential for countering overturning moments inherent in horizontal setups and heavy cutting forces, ensuring machining stability and extended machine life. Their low friction and preload design deliver exceptional micron-level positioning and repeat accuracy with long-term consistency, minimizing stick-slip. This low friction also facilitates higher feed and rapid traverse speeds, boosting productivity. Requiring minimal maintenance due to excellent sealing and low wear, they reduce operational costs and downtime, offering long service life – a key reason they are favored by reputable linear guide CNC lathe manufacturers. Furthermore, optimized designs ensure good vibration damping and minimal thermal expansion, maintaining precision during large-part or extended machining cycles. Consequently, these cnc linear guide rail systems are fundamental components for achieving enhanced rigidity, precision, efficiency, reliability, and cost-effectiveness in demanding applications.

cnc router linear guides

Linear guides for CNC, specifically linear rails for CNC router, deliver critical advantages. Their high-rigidity construction and precision rolling elements effectively absorb multi-axis cutting forces and dampen vibration, ensuring stability and contour accuracy during high-speed carving operations. The extremely low friction, combined with optimized preload, achieves micron-level repeatability while enabling rapid traverse speeds (often exceeding 60m/min) and instant starts/stops, significantly boosting productivity – ideal for intricate contours and fine details. Wear-resistant materials and fully enclosed dust-proofing drastically reduce maintenance needs and extend service life, preserving precision over time. Excellent dynamic response and thermal stability also compensate for heat-induced distortions during high-speed motion, guaranteeing dimensional accuracy across large sheet materials. CNC linear guide HGR30 and linear HGR15 CNC guide models, in particular, you can utilize DTX-LG heavy-duty linear guides SG series as a direct replacement, offering perfect interchangeability and lower cost. are favored choices among most customers due to their proven performance, solidifying these components as fundamental to achieving superior efficiency, precision, and reliability in CNC routers.

3 axes linear guide vertical cnc

CNC Z axis linear guide systems deliver critical advantages in 3-axis vertical CNC machines. They provide high rigidity to resist cutting forces and vibration across all axes, ensuring stability—especially for the cnc rail linear guide on the Z axis which must handle gravity loads and prevent settling to maintain contour accuracy. Precision raceways and optimized preload achieve micron-level repeatability, while low friction enables high feed rates (typically 30-60m/min) and instant acceleration, boosting productivity. The robust design of cnc linear rail guide components (such as HGR-series equivalents) withstands asymmetric cutting loads from vertical spindles. Fully sealed dust-proofing and long-life lubrication minimize wear, extending service life with reduced maintenance. Excellent thermal stability also compensates for deformation during high-speed operation, ensuring dimensional consistency in prolonged machining cycles. These capabilities make linear guide for CNC fundamental to achieving high precision, efficiency.

linear guide vertical cnc mill

Linear guides provide essential advantages in linear guide vertical CNC mill applications. Cnc linear slide deliver high rigidity to resist cutting forces and vibration while ensuring precise motion control. Their precision enables micron-level repeatability for complex milling tasks. Low friction allows rapid feed rates (30-60m/min) with instant acceleration, boosting productivity. The design effectively manages vertical gravity loads, preventing settling and maintaining accuracy. Sealed construction reduces maintenance and extends service life – a reliability standard also seen in high quality linear guide CNC lathe equipment. Thermal stability maintains dimensional consistency during long operations. These core benefits mirror requirements in advanced turning centers like line slider guide rail automatic slant bed CNC lathe systems. As critical CNC machine linear guide components, they form the stability foundation for precision machining, offering performance comparable to premium linear guide CNC lathe solutions.

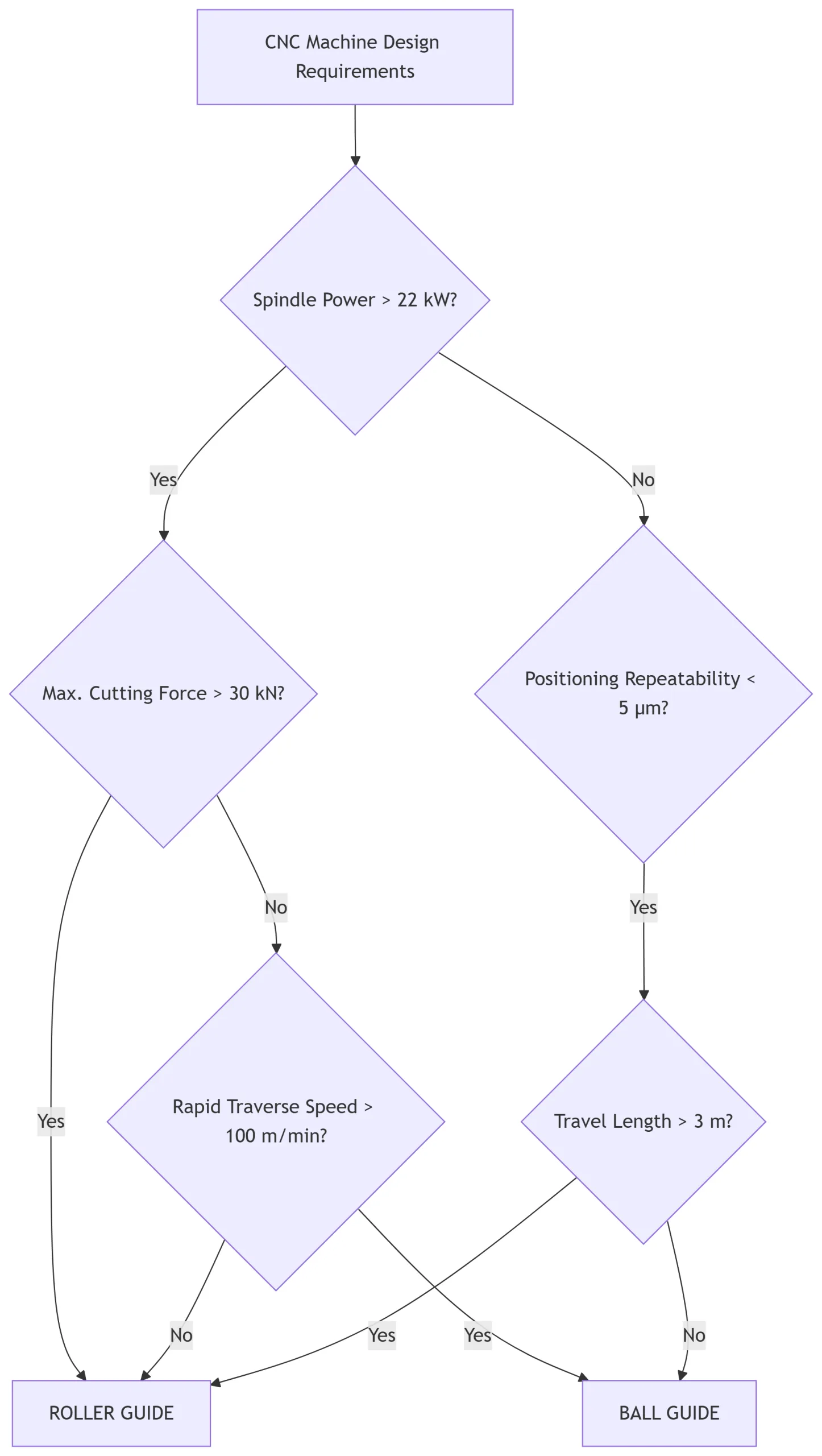

linear rails cnc Selection

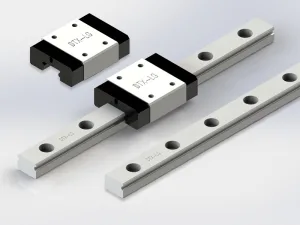

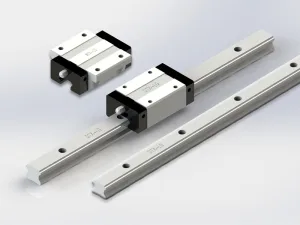

Ball-type linear guide rail CNC systems utilize point-contact design (friction coefficient: 0.001–0.003), making them ideal for high-speed applications (100–200 m/min), particularly in light-load scenarios like aluminum processing or compact equipment such as desktop engravers with CNC linear guide MGN12 600mm configurations, offering 15–30% cost savings. Conversely, roller-type guides achieve superior performance through line contact, delivering 30–50% higher rigidity and 1.5–2x lifespan – essential for heavy-load applications like HMC Z-axes or linear guide CNC lathe factory environments handling castings/titanium. They excel in impact resistance and wide-table support where offset loading occurs. For optimal selection in systems ranging from CNC guide linear 200mm setups to industrial machinery, utilize our structure tree to match guide type to your operational demands.

As a leading professional linear guide cnc manufacturer, DTX-LG has engineered solutions for linear guide cnc lathe manufacturer, addressing operational bottlenecks in CNC machine rails selection and implementation. Our linear CNC guides fast delivery capability supports global automation systems with:

- professional linear guide for cnc

- Robust linear rail CNC router integration

- Customized linear motion components

- OEM linear guide cnc lathe